|

1.Material to be conveyed:______

2.Handling capacity: ______ t/h

3.Bulk Density:______ t/m3

4.Max. Granule size of the feeding material:______ mm

5.Max.Granule's percentage in whole material:______ %

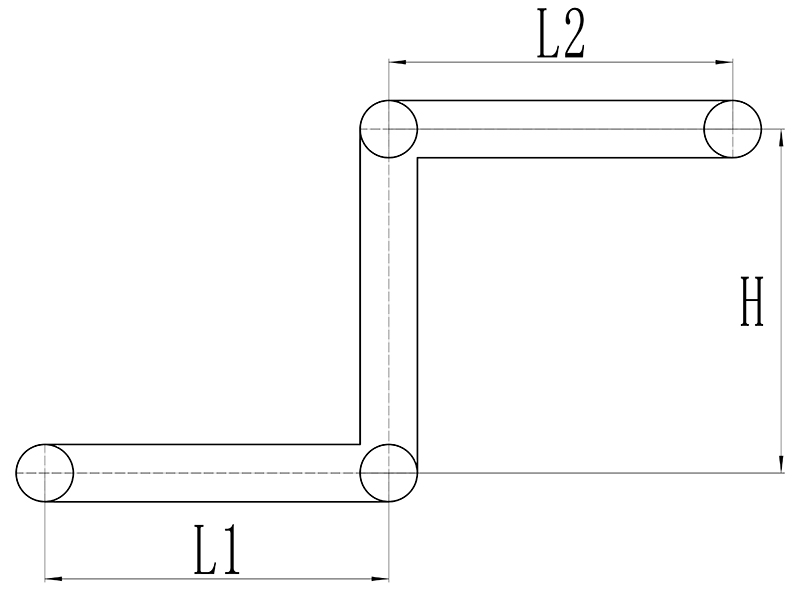

6. Please refer to the drawing to provide the corresponding size: L1=______ m; L2=______ m; H=______ m;

7.What equipment is used to feed the material into the sidewall belt conveyor :______

8.What equipment is used to discharge the material from the sidewall belt conveyor :______

9.Working power supply: ______ V ______ HZ

10.Does the sidewall belt conveyor work alone or with other equipment to form a system? If forming a system, do you have preliminary design or hand-drawn sketch? If have,please send it to our engineer for reference.

|

.jpg)

.png)

.png)

.png)

.png)

.png)

.jpg)