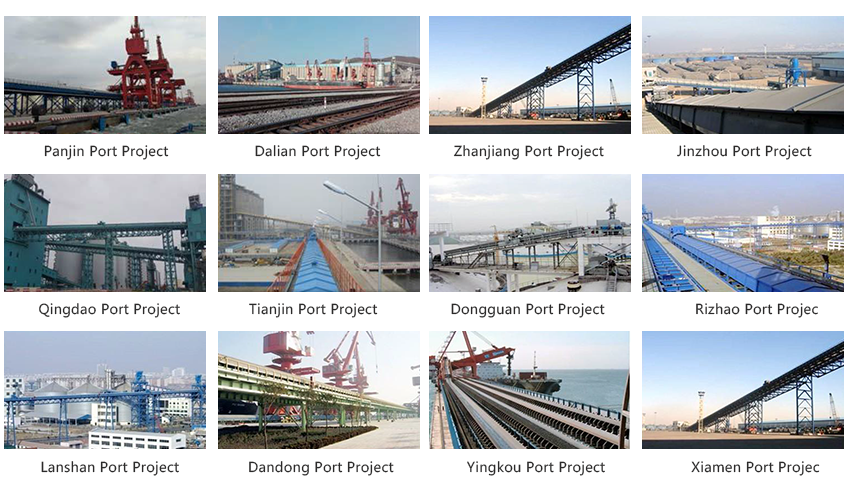

Air supported belt conveyor is universal conveyor, can be widely used in Coal, Metallurgy, Electricity, Port, Chemical Industry, Mechanical, Building Materials etc. Especially it used for conveying Grain. It can meet the requirements of these industries for large throughput.

The air supported belt conveyor provided by our company has been widely used in many industry fields, both light industry and transportation industry. The maximum conveying distance of single machine has reached more than 1 km. Speed 6m / s or more. Air supported belt conveyor have occupied huge market at home and abroad in the material conveying process.

The advantages of ASBC versus conventional conveyors

It is designed to convey free flowing dry products in all types of industries, especially in applications where dust containment is crucial. Its smooth transport and constant air flow means materials stay on the conveyor belt and dusting is practically eliminated.

1. Small power, low energy consumption, reduce the friction between conveyor belt and conveyor idler, reduced motor power

2. Under the same conditions, the power of the air supported conveyor is the same as the power of operation, no additional power increase.

3. Compared with other belt conveyors, small quantity of conveyor idlers, low maintenance costs, long service life of the belt.

4.Small friction resistance of belt,reduce 10%-20% of driving power consumption

5.Enclosed transportation can avoid flying dust and is environmentally friendly.

6. High productivity

The air supported belt conveyor can form the best material loading section. Compared with the roller belt conveyors, it can be loaded with 5%~15% material, which is suitable for high speed operation (the belt speed of the general roller machine is 1.25 rn/s, and the air supported belt conveyor generally 1.6n ∥ s ~ 2.0 hu / s), can improve the transport capacity without increasing the bandwidth.

7. Optional lightweight rubber belt and extended service life

The air supported belt conveyor has low running resistance and low tension. Lightweight rubber belt can be used. It runs smoothly, does not run off, the tape wears little, the tearing phenomenon rarely occurs, and the service life of the tape is more than doubled.

8. Can be used for large dip arrangement

The air supported belt conveyor has continuous gas support, material runs smoothly, its inclination angle is less than the static friction angle of the material and the conveyor belt. The actual angle of inclination of the air supported belt conveyor can be 18° from the roller machine. Increase to 23°. It can also run safely on the left and right.

Air Supported Belt Conveyor for Rizhao Port Grain Storage Project

Air Supported Belt Conveyor for Rizhao Port Grain Storage Project Air Supported Belt Conveyor for Tianjin Economic Zone Project

Air Supported Belt Conveyor for Tianjin Economic Zone Project.jpg) ASBC for Cargill Huanghua Port Grain and Oil Wharf Project

ASBC for Cargill Huanghua Port Grain and Oil Wharf Project.jpg) ASBC for Sinograine Xinzheng Soybean Bulk Grain Conveying System

ASBC for Sinograine Xinzheng Soybean Bulk Grain Conveying System

.jpg)