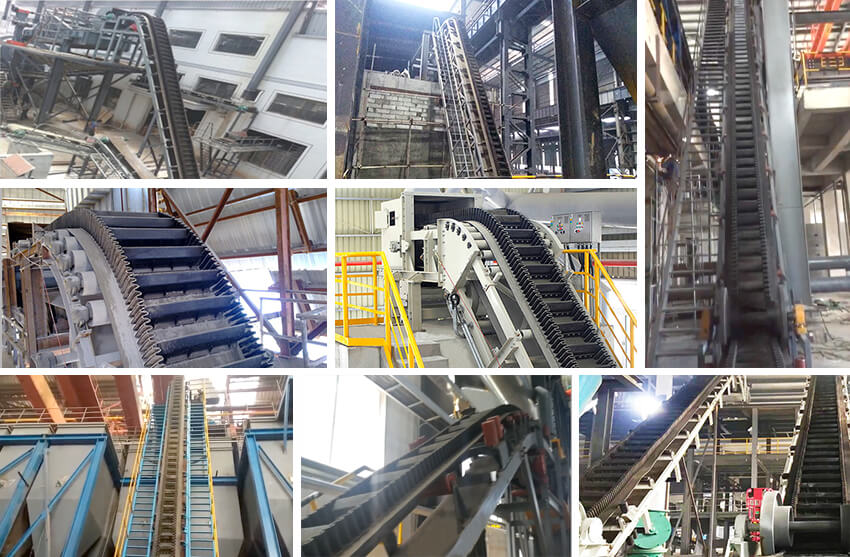

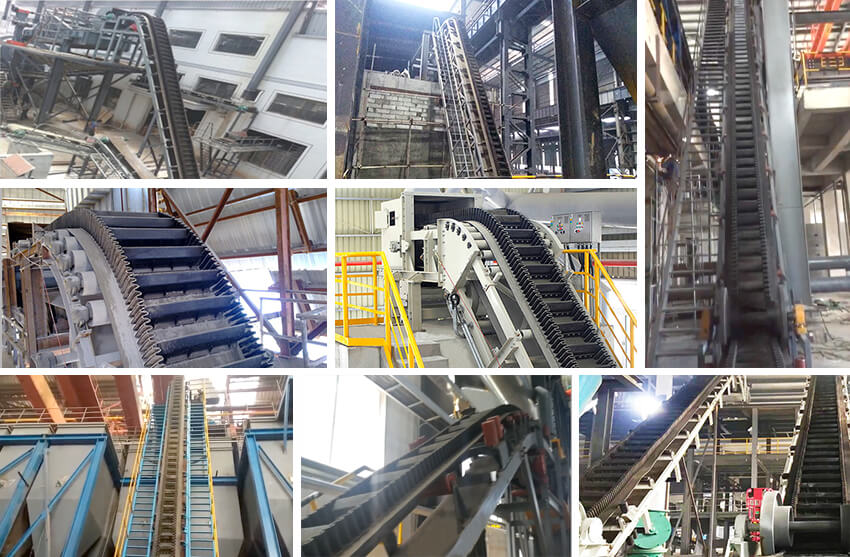

Large Angle Conveying For Reduce Conveying Length

1. Steep incline conveyors are simply slotted belt conveyors located on slopes. Traditional belt conveyors are usually ineffective when the inclination is greater than 22 degrees, because the material on the belt is slipping as a major problem. In contrast, steep slope conveyors can transport materials at inclines of up to 90°.

2. Compared with the traditional Belt conveyor, the steep inclined conveyor reduce conveying length for save nstallation space, and is more suitable for the limited space in the factory.

.jpg) STEEP INCLINE CONVEYOR COMPONENT INTRODUCTION

STEEP INCLINE CONVEYOR COMPONENT INTRODUCTION

.jpg)

STEEP INCLINE CONVEYOR FEATURES

1.Less Space Requirement

Steep Incline Conveyor can achieve large angles or vertical conveying, thus reducing the footprint, saving the construction cost.

2.Low Energy Consumption

Steep Incline Conveyor can large angles or vertical conveying which can greatly reduce conveying length, so as to effectively reduce power requirements.

3.Flexible Layout

The flexible layout of Steep Incline Conveyor can be effectively reduced number of equipment and transfer points.

4.Environmentally Friendly

The unique structure of Steep Incline Conveyor can effectively reduce material leakage, improve working condition, protect the environment.

5.Automatic Tension Adjustment

The tail of the Steep Incline Conveyor uses a screw take-up device to automatically tension the belt in the running processes.

STEEP INCLINE CONVEYOR Applications In Various Industries

Construction materials industry: transportation of cement, lime, limestone, clinker, bypass dust, secondary fuels, etc.

Construction materials industry: transportation of cement, lime, limestone, clinker, bypass dust, secondary fuels, etc.

Waste conditioning for transportation of waste material: fluff, secondary fuels, etc.

Power-generating plants: transporting coal, ashes, ground limestone, gypsum, etc.

plastics production: transporting plastic granules, etc.

Chemical industry: transport of powdered materials, granulates, minerals, etc.

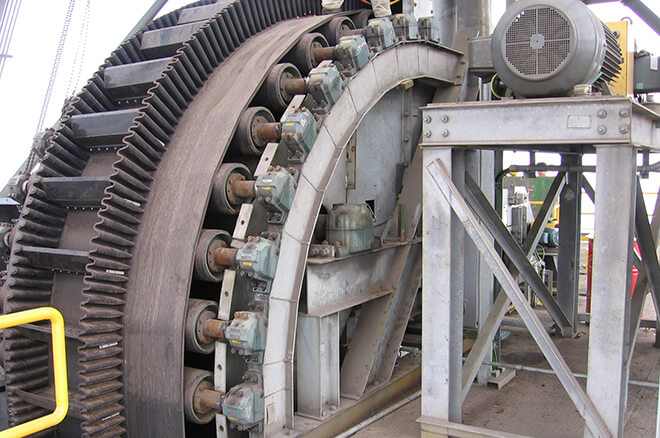

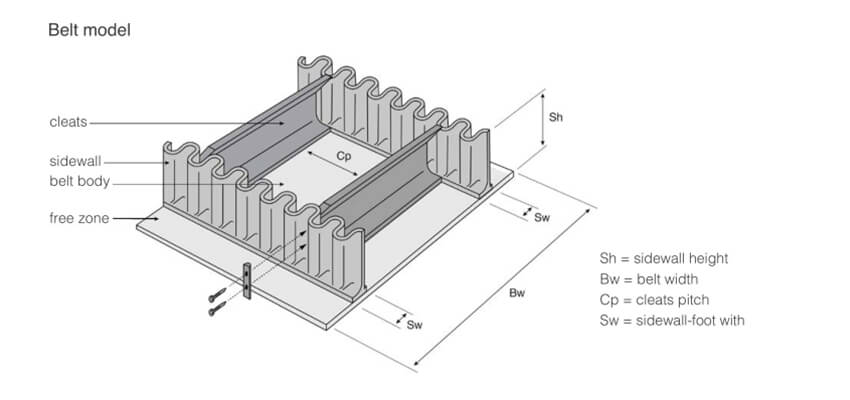

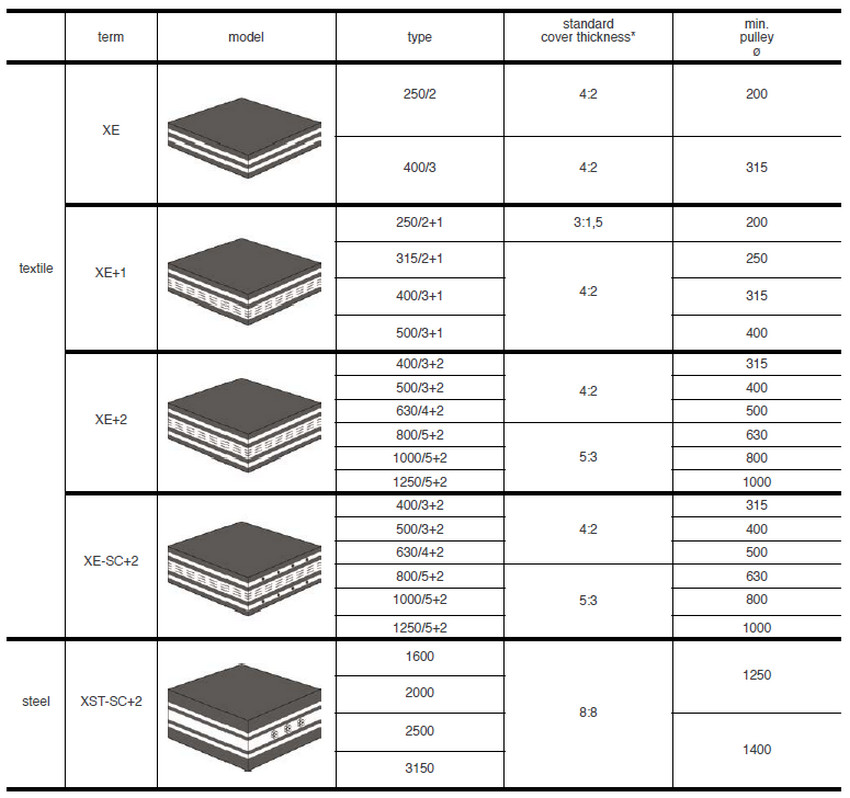

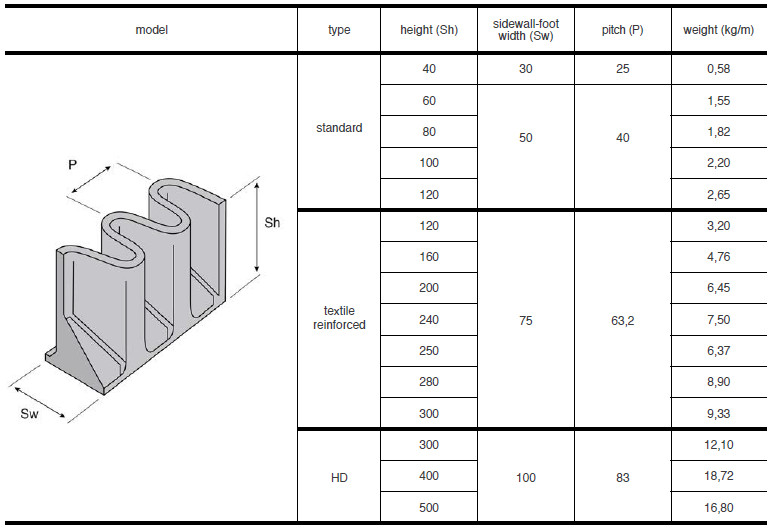

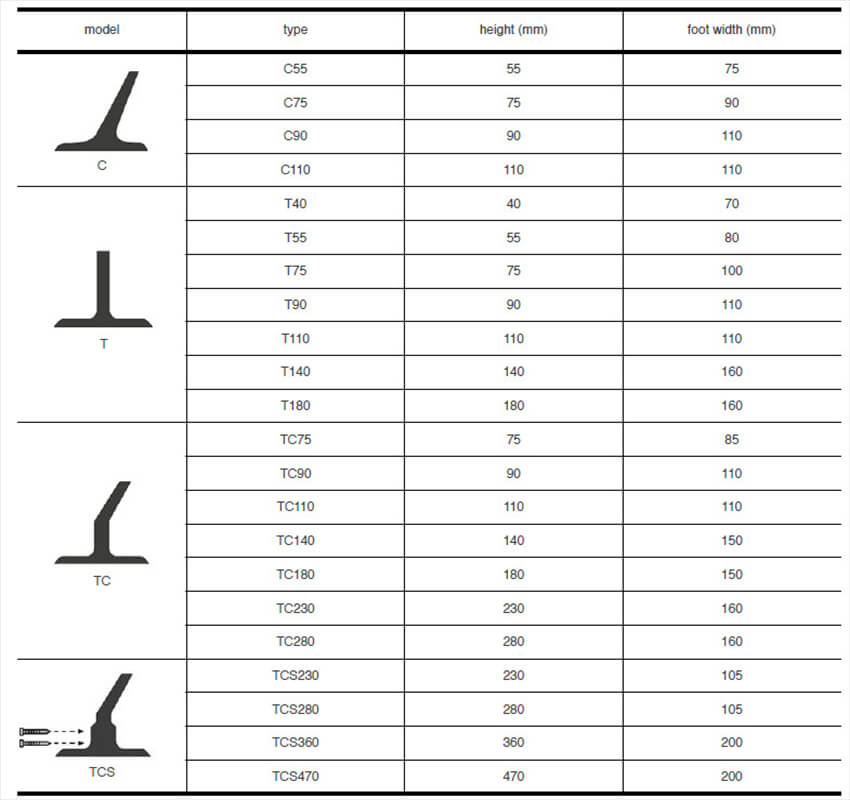

steep incline conveyor belt

Steep Incline conveyor belting acts as a barrier to keep materials from falling off the belt and is ideal for situations where products convey on an incline or decline. Corrugated sidewalls have a flexible design that’s compatible with both small and large pulley diameters. Our sidewall conveyor belts will help maximize product load capacity to improve your conveyor systems overall efficiency, resulting in bottom line growth.

STEEP INCLINE CONVEYOR BELT PACKAGE AND DELIVER

.jpg) |

1.Material to be conveyed:______

2.Handling capacity: ______ t/h

3.Bulk Density:______ t/m3

4.Max. Granule size of the feeding material:______ mm

5.Max.Granule's percentage in whole material:______ %

6. Please refer to the drawing to provide the corresponding size: L1=______ m; L2=______ m; L3=______ m; α=______ °

7.What equipment is used to feed the material into the sidewall belt conveyor:______

8.What equipment is used to discharge the material from the sidewall belt conveyor :______

9.Working power supply: ______ V ______ HZ

10.Does the sidewall belt conveyor work alone or with other equipment to form a system? If forming a system, do you have preliminary design or hand-drawn sketch? If have, please send it to our engineer for reference.

|

.jpg)

.jpg)

.jpg)