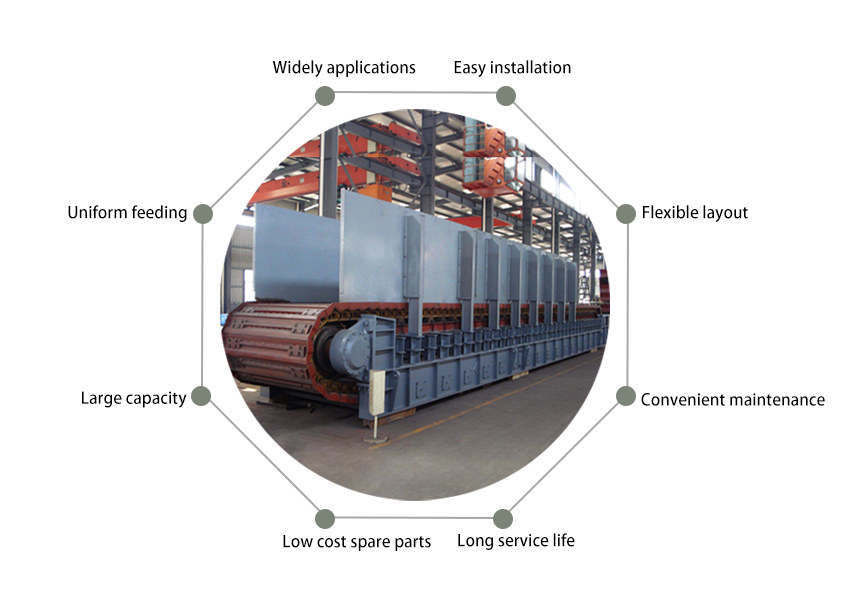

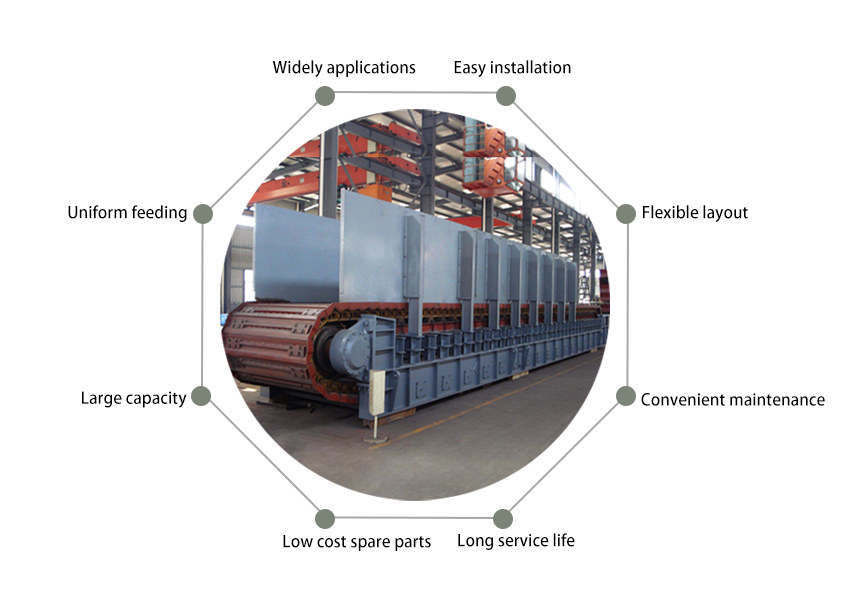

main component DETAILS & FEATURES

.jpg) |

|

|

Pans

According to different working conditions, we will choose the most suitable design to meet your requirements. For example, we use manganese pans to replace cast steel pans, with a longitudinal center rib, avoiding excessive deflections under high-impact loading and severely abrasive working conditons.

|

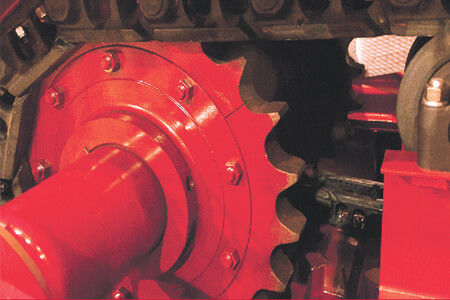

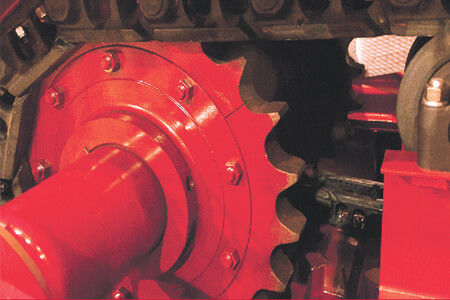

Sprocket

Sprocket design features three cast manganese alloy steel segments that allow replacement of one segment at a time, without needing to dismantle the feeder or remove the chain, pans, skirts and material on the feeder.

Rather than taking multiple shifts to change out the drive sprockets, the upgraded design allows a changeout in just hours. In addition, a half-tooth design with an odd number of teeth is used to allow contact with the chain during every second revolution, which doubles the life of the sprockets. |

.jpg) |

|

|

Chains

The track chain is used in our apron feeder, because the pin and bush are made of heat-treated alloy steel. To withstand greater weight, the chain link is made by drop forging, which can effectively prevent the external sands entering, thus, prolong the chain life.

|

Rollers

Single flange tractor type rollers are mounted on support members in groups of 2 to 4 units to make disassembly and replacement easier.

|

1.Using 16Mn steel plate with high strength and stiffness, to withstand great impact.

2.Standard track chain, no lubrication or deviation, for interchangeability and long service life.

3.The sprocket material is made of high strength alloy steel and quenched, which has excellent wear resistance.

4.Equipped with composite spring on the tail part, which can effectively buffer the impact load of the chain.

5. Segmented drive sprockets, easy to maintain without removing the chain plate.

6.Traction chain and load chain are separated, so the dynamic load is small to achieve exteneding life.

SUCCESS PROJECT IN VARIOUS INDUSTRIES

|

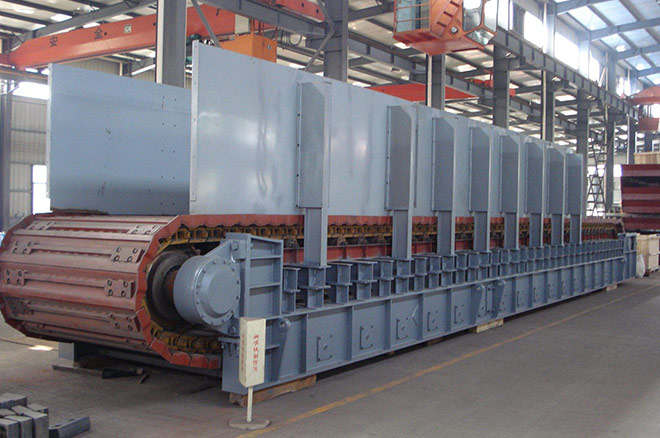

Project Name: Heilongjiang Duobaoshan Copper Co., Ltd. Phase II Expansion Project

Equipment Model: BL1600-11.0

Pan Width: 1,600mm

C-C Distance: 11,000mm

Angle of Installation: 0°

Handling Material: Prophyry Copper Mine

Handling Capacity: 2,000t/h

Customer Name: Heilongjiang Duobaoshan Copper Co., Ltd.

|

|

|

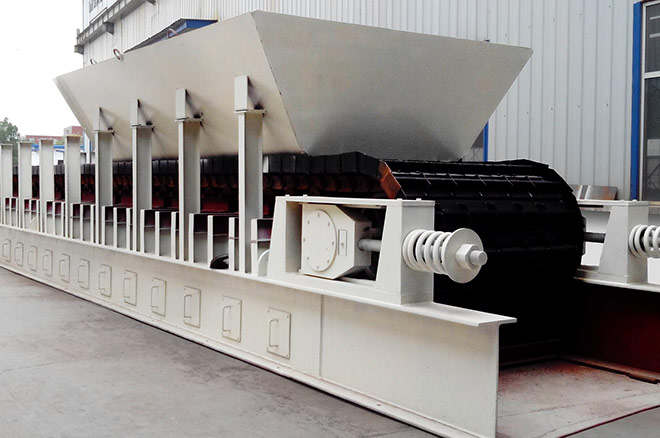

Project Name: Limestone crushing & screening system for Qinghai Construction Co.,Ltd.

Equipment Model: BL1800-6.0

Pan Width: 1,800mm

C-C Distance: 6,000mm

Angle of Installation: 12°

Handling Material: Limestone

Handling Capacity: 1,200t/h

Customer Name: Qinghai Construction Co.,Ltd.

|

.jpg) |

Project Name: Coal crushing & screening & conveying project for Xinjiang Zhongtai Chemical Co., Ltd

Equipment Model: BL2400-9.0

Pan Width: 2,400mm

C-C Distance: 9,000mm

Angle of Installation: 10°

Handling Material: Coal Gangue

Handling Capacity: 2,500t/h

Customer Name: Xinjiang Zhongtai Chemical Co., Ltd |

| Apron Feeder Technical Specifications |

| Model |

Pan width

(mm) |

Speed

(m/s) |

Max feeding size

(mm) |

Rail

(pcs) |

Capacity

(m³/h) |

Length(m) |

| BL800 |

800 |

0.01~0.25 |

350 |

/ |

50~350 |

2~15 |

| BL1000 |

1000 |

0.01~0.25 |

470 |

1 |

100~510 |

3~20 |

| BL1200 |

1200 |

0.01~0.2 |

650 |

1 |

120~595 |

3~20 |

| BL1400 |

1400 |

0.01~0.2 |

680 |

2 |

140~850 |

6~20 |

| BL1600 |

1600 |

0.01~0.2 |

700 |

2 |

320~1300 |

6~20 |

| BL1800 |

1800 |

0.01~0.15 |

800 |

2 |

500~1560 |

8~20 |

| BL2000 |

2000 |

0.01~0.15 |

1000 |

3 |

500~1850 |

8~20 |

| BL2400 |

2400 |

0.01~0.15 |

1500 |

3 |

500~2700 |

8~20 |

| BL2800 |

2800 |

0.01~0.15 |

1800 |

4 |

1000~4000 |

10~20 |

1.Which material to be handling:______

2.Handling capacity: ______t/h

3.Material density: ______t/m³

4.Center distance between the head sprocket and tail sprocket :______m

5.Is the layout of the apron feeder inclined or horizontal ? If it is inclined,what is the inclined degree______°

6.Max. granule size of the feeding material: ______mm

7.Max. Granule’s percentage in whole material:______ %

8.What equipment is used to feed the material into the apron feeder:______

9.What equipment is used to discharge the material from the apron feeder:______

10.Working power supply: ______V ______HZ

11.Required quantity: ______

12. Under normal circumstances, the upstream equipment of the apron feeder is the hopper. In order to facilitate our engineers to calculate the power of the apron feeder, can you provide the preliminary design scheme or hand-drawn drawings of the hopper?

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)