These switches are designed for the safety of people and machines to avoid accidents and to stop the machine in an emergency.

In belt conveyors, belt sway can result from uneven loading, misalignment of the idler set, and worn surfaces. Belted sway switches are useful to limit belt swings to tolerable limits. It is best to install the belt swing switch every 15 to 20 meters on both sides of the belt conveyor.

1. Smooth movement of roller ensures long life.

2. Automatic Reset when belt resumes normal Position.

3. Switches are protected against accidental over travel of the operating lever.

4. Standardized design and moulded construction allows interchangeability of parts.

| Output Contacts |

1NO+1NC or 2NO+2NC contacts are available as per customer requirement. |

| Termination |

Suitable to accept 2.5 mm sq conductors. Separate earthing studs are provided |

| Housing |

DMC or Cast Aluminium, Dust and Water tight to IP – 65 grade. Cast Iron Enclosure available optionally |

| Contact Rating |

16 Amp at 440V AC on resistive load. They are suitable for lower rating also. (e.g. 5A at 240V AC) |

| Service life |

Reliable action 100,000 times |

| Model |

Acting force |

Contact rating |

Switch action Angle |

Weight |

Protection level |

| |

|

Normal open |

Normal close |

First Grade |

Second

Grade |

Limiting Angle |

|

|

| XKPT1 -12-30 |

20-70N |

2 |

2 |

12° |

30° |

75° |

3.5KG |

IP65 |

| XKPT1 -10-45 |

20-70N |

2 |

2 |

10° |

45° |

75° |

3.5KG |

IP65 |

| XKPT1 -20-35 |

20-70N |

2 |

2 |

20° |

35° |

75° |

3.5KG |

IP65 |

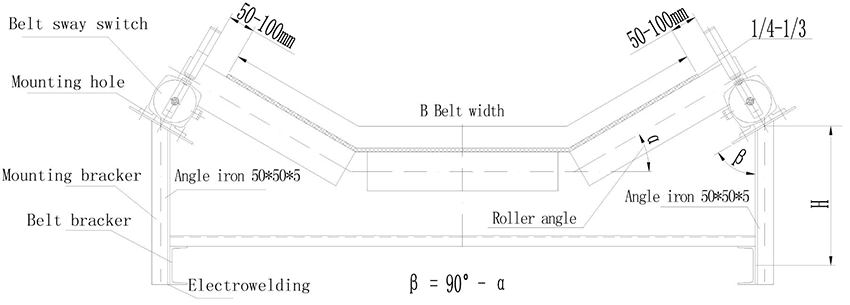

1.The deviation switch shall be installed on both sides of the belt conveyor, and the position of the deviation switch should be such that the vertical roller is perpendicular to the belt side plane and the belt side edge is fixed at 1/4-1/3 of the roller in a suitable position.

2.The distance between the vertical roller and the belt should normally be within the natural offset of the belt, plus 50~100 mm.

3.3. The deviation switches are mounted in pairs at the head, tail and intermediate positions. In general, three pairs of tapes having a length of 100 meters are suitable.

4.After the mounting bracket is welded or bolted to the machine frame, tighten the running switch to the mounting bracket with bolts.

|

Project: Belt Sway Switch Used for Coal Belt Conveyor Protect System

Quantity: 40 pcs Application: Coal Industry

Customer: NeiMengGu Shang Tong Coal Co., Ltd.

|

|

|

Project: Belt Sway Switch Used for Belt Conveyor Protect System In Sand Plant

Quantity: 30 pcs Application: Construction Industry

Customer: ChongQing Heda Sand Co., Ltd. |

|

Project: Belt Sway Switch Used for Belt Conveyor Protect System In Steel Mills

Quantity: 32 pcs Application: Mining Industry

Customer: Anyang Steel Mills Co., Ltd. |