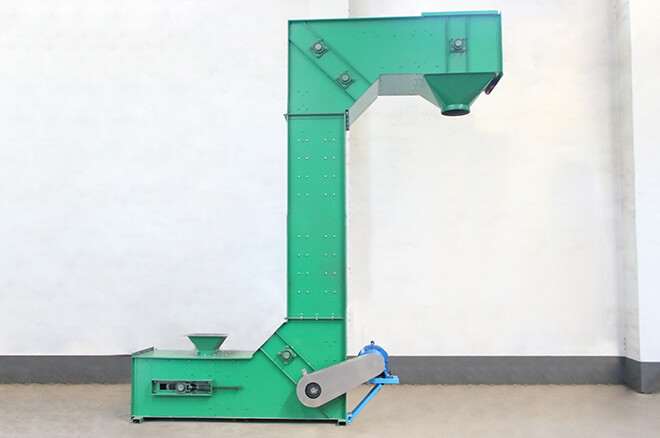

The Bucket Elevator is designed to lift various materials up to the delivery position at the top of the machine.The buckets are suspended in continuing hollow chains that are pulled by a gear motor installed at the top horizontal arm and located on the outside of the steel plates.The material inlet is located at the lower horizontal arm and is consisting of a vibration feeder and brushing devises that provide continues and consistent flow of the material to the buckets.The unit is mounted with inspection hatches for service and maintenance. There is a draw in the lower section allowing for easy cleaning.

If you need elevator buckets, please click here

https://www.exctmach.com/products/spare-parts/elevator-buckets.html

Increased full range of ultra-high polymer guide rails and chain friction blocks, equipped with a check device and electronic detection device, chain breaking protection device, chain automatic tension device at a higher lifting height, making the equipment more secure and reliable.

The lifting chain uses a high-strength chain, which continues the characteristics of our food-grade plastic hopper in the size of the hopper.

Combined with anti-corrosion, high temperature and other requirements, R & D designed a special stainless steel hopper.

The machine is combined in a sectional style, with optional horizontal length and lifting height. Flexible layout, small footprint, saving plant space, reduce pit depth.

Operation is safe and reliable, smooth and lower noise, few dust, easy to open and easy to repair, is an ideal new type of material conveying equipment.

Rugged design,Long service life.

Made from stainless steel/painted mild steel.

Bearing jack bolts for shaft alignment.

Hinged lagging inspection door with quick latch.

Z type bucket elevator DETAILS

|

Driving Device

We have long cooperated with famous international brand, such as SEW, Siemens, also with some domestic brand, such as YUTONG, TaiLong, internation trade. The motor has long service life, steady operation, save energy and environment protection. |

Chain

The chain with excellent quality alloy steel guarantees the strength, simple structure, high abrasive resistance, reliable operating, convenient to disassembly and assembly, flexible ratoring and low running noise. |

|

|

Sprocket

Z bucket elevator uses the alloy steel/ stainless stell sprocket wheel, high strength, good bite force with chain, great abrasive resistance, long service life, easy to disassembly and assembly, convenient to replacement. |

|

Bucket

The bucket can be customed based on client's use requirements, ABS acrylonitrile butadiene styrene bucket, high quality stainless steel and ordinary carbon steel bucket can be choice. Our bucket has heat resistance, corrosion resistance, good flame retardant performance, high strength, great fluidity, not stick material, etc.

|

|

|

Tensioning Device

Our bucket elevator uses the screw tension device to adjust the tightness of the chain, which can effectively prevent the chain from slipping and prevent the chain from breaking due to too tight. Tension device has simple structure, convenient to adjustment.

|

| Model |

CTZD-2L |

CTZD-5L |

CTZD-7L |

| Capacity/Bucket |

2L |

5L |

7L |

| Speed |

9-11m/min |

9-11m/min |

9-11m/min |

| Processing Capacity |

4-8m³/h |

12-15m³/h |

15-17m³/h |

| lifting Height |

Customized |

Customized |

Customized |

| Power |

0.75-7.5KW |

0.75-7.5KW |

0.75-7.5KW |

| Box Sized |

628x420 |

750x500 |

820x650 |

In order to give you scientific selection and accurate quotation, our engineers also need to confirm the following information:

1.Material to be handling:______

2.Handling capacity:______t/h

3.Bulk Density: ______t/m3

4.Max. granule size of the feeding material: ______mm

5.Vertical distance from the feeding inlet to discharge outlet:______m

6.Length of the upper horizontal segment:______ m

7.Length of the bottom horizontal segment:______ m

8.What equipment is used to feed the material into the Z bucket elevator :______

9. What equipment is used to discharge the material from the Z bucket elevator :______

10.Working power supply: ______V ______HZ

11.Does the Z bucket elevator work alone or with other equipment to form a system? If forming a system, do you have reliminary design or hand-drawn sketch? If have,Please send it to our engineer for reference.

12.Quantity:______

.jpg)