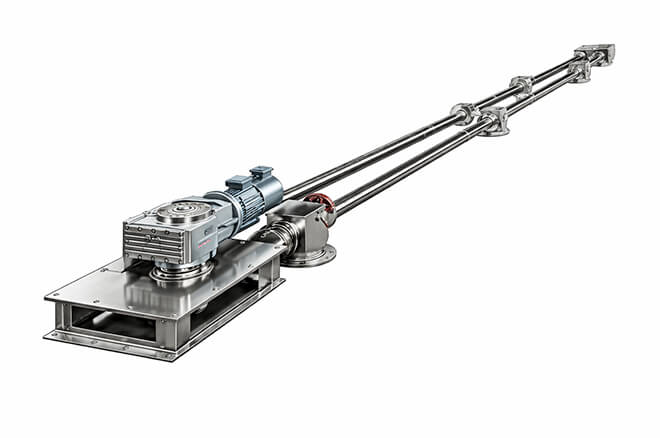

Enclosed, Dust-Free Conveying

Enclosed, Dust-Free Conveying

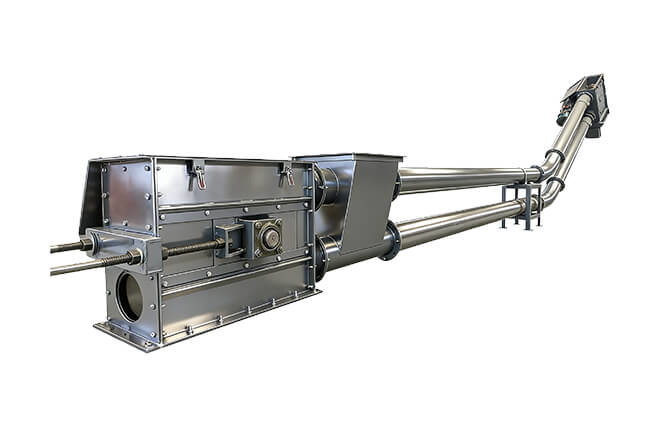

Tubular drag conveyors feature a fully enclosed tube design, ensuring clean, controlled bulk material transport while meeting environmental and safety requirements.

Gentle Low-Speed Operation

Gentle Low-Speed Operation

Low-speed chain and disc conveying reduces product breakage, segregation, and fines, preserving material quality throughout the process.

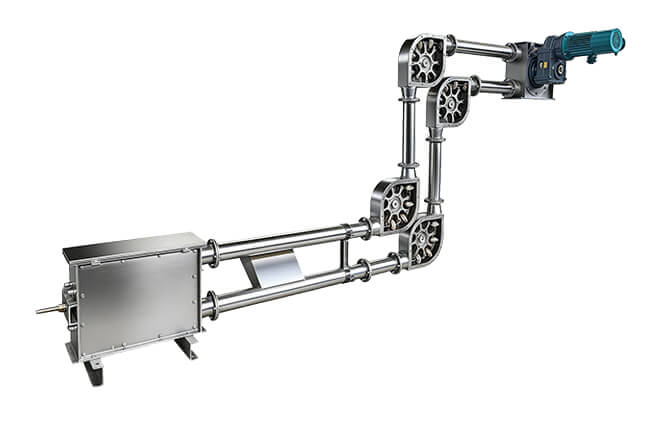

Flexible Multi-Direction Layout

Flexible Multi-Direction Layout

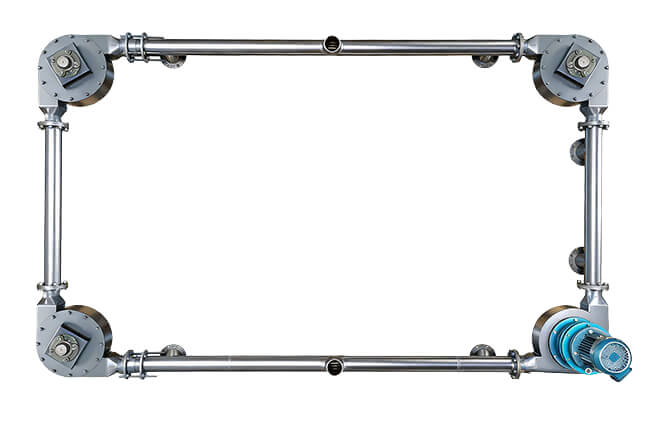

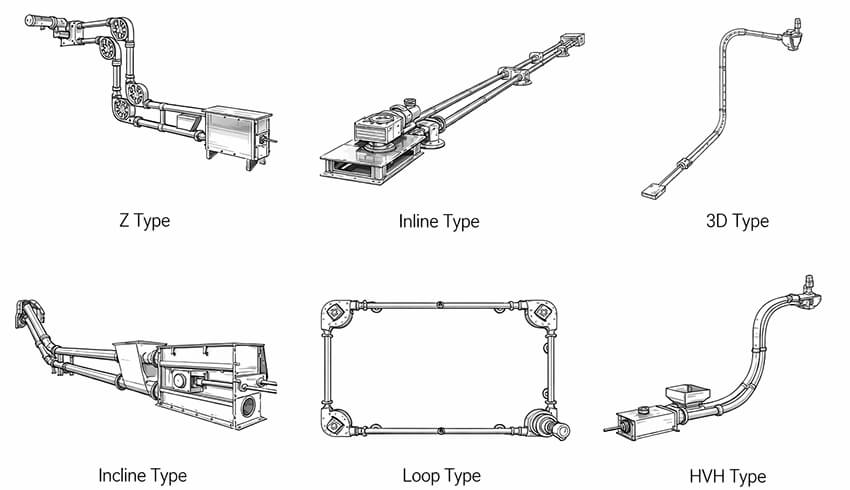

Supports horizontal, vertical, and curved conveying paths, enabling easy integration into compact spaces and complex plant layouts.

Broad Material Compatibility

Broad Material Compatibility

Handles powders, granules, flakes, and mildly abrasive materials with consistent, reliable performance.

Energy-Efficient Operation

Energy-Efficient Operation

Low drive power and reduced wear result in lower energy consumption and operating costs.

Scalable Modular Design

Scalable Modular Design

Modular construction allows easy system expansion, capacity adjustment, and line integration.

.jpg)

.jpg)

.jpg)