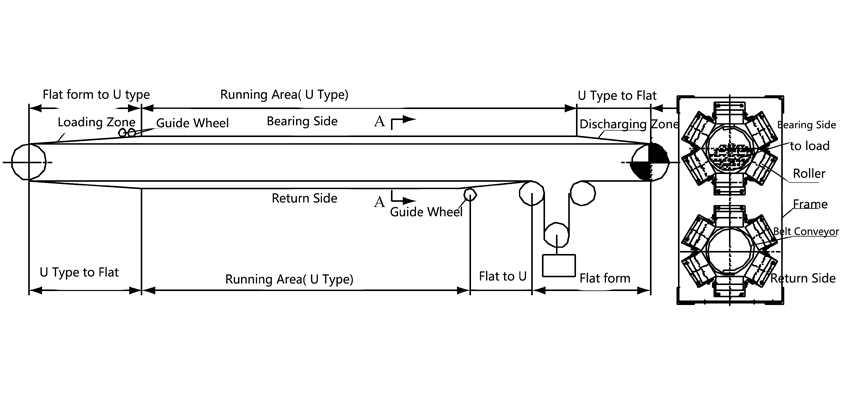

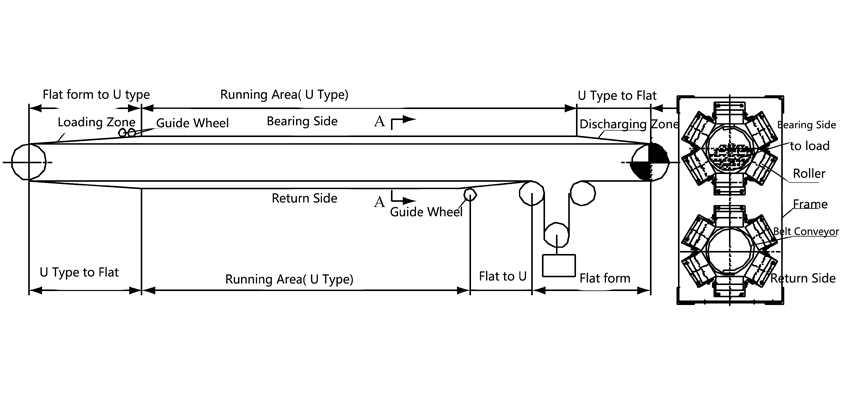

The belt is rolled into a tubular shape and can be bent in any direction with a small radius of curvature, thereby expanding the use range of the conveyor, and providing a theoretical basis for the layout design of the curved section of the

pipe conveyor. It can solve problems and create value for users in a better way.

1.Factors affecting the radius of curvature of

pipe conveyors

The radius of curvature of the pipe conveyor is determined by the diameter of the pipe, the type of conveyor belt and the layout line. It needs to be comprehensively considered according to the static and dynamic tension of the conveyor belt.

(1)Influence of conveyor belt type

The belt will be rolled into pipe when it runs. It should have proper lateral rigidity, good tubular retention and sealing, and has good elasticity and longitudinal flexibility. It ensures that the conveyor belt can pass through the transition section and roll into tubular operation in the feeding section, and the unloading roller is carried out. The special nylon polyester belt should be used for this belt, which has excellent physical and mechanical properties. The outer covering adhesive has high weather resistance, ozone resistance, UV resistance, flexion resistance and other properties, while the inner cover adhesive should have excellent wear resistance. The elastic modulus of the core material of the belt is an important factor determining the curvature radius of the curved section of the

pipe conveyor.

(2)Influence of bending type

The different of bending form and force of the running belt has an important influence on determining the radius of curvature of the curved section of the

pipe conveyor.

(3) Influence of pipe diameter

The diameter of the pipe conveyor determines the width of the belt used, and also determines the difference between the radius of curvature of the inner and outer arcs of the curved section and the difference between the strain at the edge of the belt and the center. Generally, the diameter of the pipe diameter is determined according to the conveying amount, the belt speed, and the lump of material, and the radius of curvature is proportional to the pipe diameter.

(4) influence of belt tension

The point by point calculation method for bending section tension of pipe conveyor is the same as general belt conveyor. The tension of the curved section is large and the elongation of the belt is large. It is necessary to increase the radius of curvature and increase the rigid resistance of the belt conveyor. When the radius of curvature is small, the roller is subjected to a large force, which affects the service life of the roller.

2 Determination of the radius of curvature of the pipe conveyor bending

The theoretical analysis shows that the curvature radius of the curved section of the

pipe conveyor is usually determined by the pipe diameter, the type of the conveyor belt and the bending form, and the smaller radius standard is generally recommended (Table 1). However, due to the interference of terrain and buildings, it is necessary to arrange lines according to the maximum radius of curvature according to the specific terrain conditions, calculate the tension of the curved section, then determine the belt type, and after that verify the rationality of the curvature radius of the belt based on the above theory.

The force on the two sides of the convex arc bending belt is larger than the center. It is usually easy to twist in the course of operation, so the line should be avoided this situation as far as possible. Usually, the curvature radius of convex arc section is larger than that of concave arc section.

Space bending is feasible in pipe conveyor. Properly increase the curvature radius of the line layout, reduce the number of space bending as much as possible, so as to reduce the cost of equipment.s

Table 1 recommended table for curvature radius of

pipe conveyor

Bending Type Nylon Conveyor Belt Steel Cord Notes

|

Bending Type

|

Nylon Conveyor Belt

|

Steel Cord

|

Notes

|

|

Horizontal Bending

|

300D

|

700D

|

D is the radius

|

|

S Type Bending

|

400D

|

800D

|

|

Convex Arc Bending

|

400D

|

800D

|

|

Concave Arc Bending

|

300D

|

700D

|

|

Concave Arc + Horizontal

|

400D

|

800D

|

|

Convex Arc + Horizontal

|

500D

|

900D

|

3 Conclusion

The curvature radius of the carved section of the

pipe conveyor should be determined according to the Table 1. First, select the data not less than table 1 provided; secondly, according to the terrain and building, it should satisfies the curvature radius of line direction, check the formula, pay attention to the starting point position of the curved section and the angle of bending.