Introduction

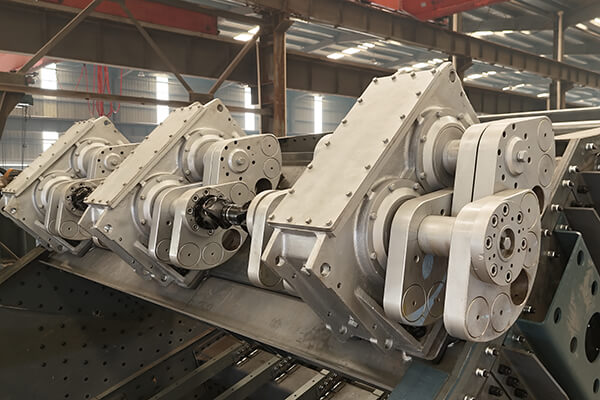

The application of Banana Screen in industrial fields such as mineral processing, coal, and building materials can quickly achieve material classification, desmedium removal, and dehydration treatment. Banana Screen, with its advantages of high processing capacity and high screening efficiency, has become a key device. The core of its stable operation lies in the coupling.

Transmit power and torque

The vibration power of Banana Screen comes from the rotational motion of the motor. The coupling stably transmits the rotational power of the motor to the eccentric shaft of the vibrator, and then converts it into the reciprocating vibration of the screen body through the rotation of the eccentric shaft. Through the design of rigid or elastic structure, it ensures the efficient transmission of power from the input end to the output end. Avoid the decline in screening efficiency caused by power loss.

Torque transmission

When the Banana Screen processes materials of different particle sizes and densities, the load of the screen body will fluctuate. This requires the coupling to have a stable torque transmission capacity, which can not only maintain a uniform output of torque under the rated load, but also avoid the impact of sudden torque changes on the motor and vibrator when the load fluctuates instantaneously.

Adapt to the load

The load of Banana Screen has "dynamic fluctuation", especially when handling viscous materials or large pieces of materials, the peak load may reach 1.2-1.5 times the rated load. Couplings are usually designed with an elastic structure. When the load increases, they absorb part of the energy through elastic deformation, reducing the impact of power transmission. Quickly restore deformation when the load is reduced to ensure the stability of torque transmission.

Comparison of the power transmission advantages of different types of couplings

Elastic pin coupling

The Banana Screen has a simple structure and low cost. It is suitable for medium and low loads, and the power transmission efficiency can reach more than 98%.

Diaphragm coupling

The metal diaphragm is adopted as the elastic element, which is heat-resistant, wear-resistant, has high power transmission accuracy and is suitable for large Banana screens with high load and high speed.

Plum blossom elastic coupling

It has good elasticity and excellent buffering performance, can effectively absorb vibration, and is suitable for screening scenarios with large load fluctuations.

Compensate for misalignment and displacement

The problem of misalignment during the operation of Banana Screen

During the installation and operation of Banana Screen, the main causes of the misalignment problem include: the centerlines of the motor and the vibrator are not precisely aligned during installation; During the operation of the equipment, the vibration of the screen body causes the base to deform, which in turn leads to the deviation of the axis center. The temperature difference between the motor and the vibrator causes the components to expand and contract thermally, resulting in changes in the position of the shaft center.

All-round compensation mechanism

For radial misalignment, the two shaft centerlines are parallel but offset. The elastic coupling compensates for this through the radial deformation of the elastic element. For axial misalignment, if the two axis centerlines coincide but there is a gap or offset in the axial direction, compensation is made through the axial expansion or sliding structure of elastic elements. For angular misalignment, if the two axes intersect at a certain Angle, compensation can be achieved through the bending deformation of the elastic element or the structure of the universal joint.

Absorb vibration and shock

When the Banana Screen is running, the rotation of the motor and the vibrator will generate periodic vibrations. If they are directly transmitted to the device body, it will cause component loosening and shortened lifespan. Couplings can effectively absorb part of the vibration energy and reduce the vibration transmission efficiency through the deformation of elastic elements. When the equipment starts up, stops or experiences sudden load changes, the coupling can buffer the instantaneous impact load, prevent the rigid impact on the motor and vibrator, and play a protective role of "shock absorption and buffering".

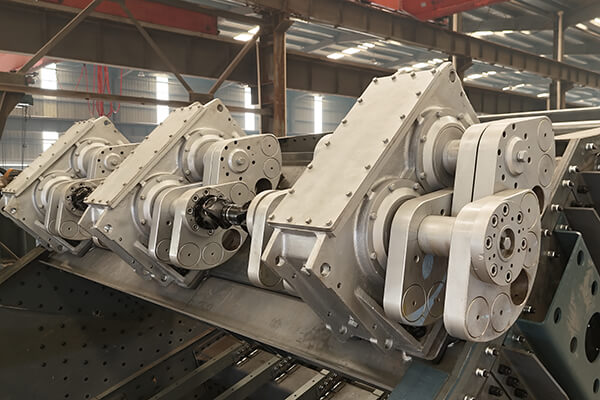

Structure and Maintenance

Material selection

The material selection of couplings directly determines their functional stability and service life. The material requirements for core components are as follows: Metal parts such as flanges usually adopt 45 # steel or alloy steel, and after quenching and tempering treatment, their strength and wear resistance are enhanced to ensure they can withstand large torques. The material of the elastic element is selected based on the application scenario. Natural rubber is used in common scenarios, silicone rubber in high-temperature scenarios, and metal diaphragms or polyurethane in high-strength scenarios. The connecting bolts adopt high-strength bolts to prevent loosening due to vibration during operation.

Daily maintenance

To ensure the long-term performance of the coupling, daily maintenance should follow the "look, listen, measure" three-step method: "Look" means checking whether the elastic elements have cracks, aging, wear and other conditions, whether the flange connection is loose, and whether the seal is intact; "Listen" means to monitor the coupling during operation for any abnormal noise. If there is a "clicking" sound, it may indicate damage to the elastic element; if there is a "buzzing" sound, it may suggest severe misalignment. "Measurement" means regularly measuring the vibration value and temperature of the coupling. When the vibration value exceeds the standard (usually ≤4.5mm/s) or the temperature exceeds 80℃, the machine should be stopped in time for inspection.

Common Fault Diagnosis

Damage to the elastic element

It is manifested as increased vibration and abnormal noise. The solution is to replace the elastic element of the same model and check the misalignment at the same time.

Loose flange connection

It is manifested as unstable power transmission and local heating. The solution is to tighten the bolts and use anti-loosening washers.

Serious misalignment

It is manifested as accelerated bearing wear and increased coupling temperature. The solution is to recalibrate the shaft centerlines of the motor and the vibrator to ensure alignment accuracy.

Conclusion

The optimization of coupling functions has a direct impact on the operational efficiency of Banana Screen: Selecting the type of coupling suitable for the working conditions can enhance the power transmission efficiency, strengthening the misalignment compensation capacity can reduce the equipment failure rate, and scientific maintenance can extend the service life of the coupling, thereby reducing the equipment operation and maintenance costs.

.jpg)