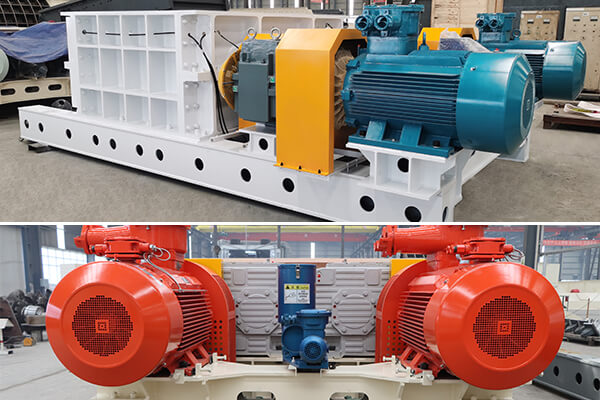

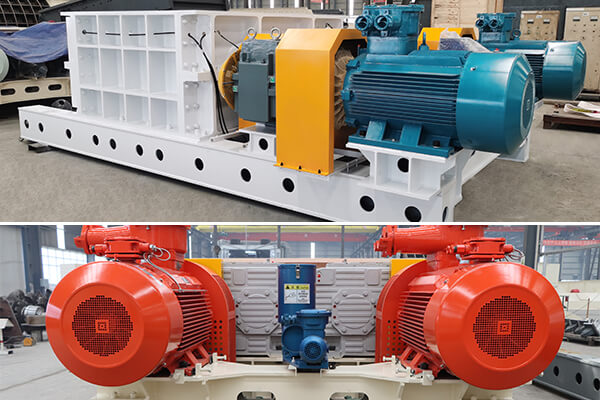

Mineral sizers is a kind of crushing equipment especially suitable for open pit coal mine. It can be used for crushing coal, coke, topsoil and other materials. Mineral sizers lubrication system plays a very important role in the positive operation of this equipment. Our company introduces automatic lubricators with the help of material network. Below is a detailed description of our mineral sizers' automatic lubricators.

Intelligent lubrication system (can achieve unattended)

(1) Lubrication of bearings.

Mineral sizers is equipped with a centralized automatic lubrication system. The automatic lubrication system can set the number of oil filling and the time of oil filling to ensure effective and reliable lubrication of all parts. Automatic control of oil supply intermittent time: AC explosion-proof oil filling motor, can be a long time uninterrupted oil supply operation: The oil supply pressure is large, the oil supply speed is fast, and the bearing is fully lubricated effectively, so that the core component of the tooth roll - the bearing is well lubricated, which greatly extends the service life of the tooth roll, makes the service cycle of the whole machine longer, and reduces the work intensity and cost of daily maintenance, usually using M0S2 extreme pressure No. 2 lithium base grease. Add 220# medium-load industrial gear oil in winter and 320# medium-load industrial gear oil in summer to keep the oil not lower than the safe oil mark position. When the ambient temperature is lower than -20 ° C, add a heating device. The project must be equipped with a heating device in winter according to the actual temperature on site. The device is automatic constant temperature control, and adopts sensors to automatically measure temperature and automatically start and stop heating. The lubrication method adopted in this project can achieve the effect of reducing the labor intensity of workers: the lubrication without spare main bearings is automatically lubricated by an automatic lubrication system, which can meet the oil storage capacity of 15-20 days, and the system can be unattended during normal operation.

(2) Lubrication of reducer.

Add 220# medium-load industrial gear oil in winter and 320# medium-load industrial gear oil in summer to keep the oil not lower than the safe oil mark position. When the ambient temperature is lower than -20 ° C, add a heating device.

(3) Lubrication of torque limited hydraulic coupler.

Mineral sizers limited torque hydraulic coupler bearing with double seal structure, no contact with the transfer medium, with independent lubrication measures, resulting in a long service life of the bearing. The working medium is water or emulsion, which must be filtered before on-site injection and must not contain sediment and impurities. Antifreeze can also be used instead of water in cold areas. The coupler is selected according to the size of the reducer and motor. The torque meets the requirement of crushing strength and has a certain surplus coefficient. Its product technology, specifications and quality meet the relevant national standards.