Apron feeder is a feeder for large pieces of material. Such as coal, ore, gravel, etc. Because of its unique impact resistance, it is widely used in all walks of life. The following are the problems encountered by our Xinjiang cement clinker customers in the process of use and the speed adjustment measures we have made in response to the problem:

1 Question raising

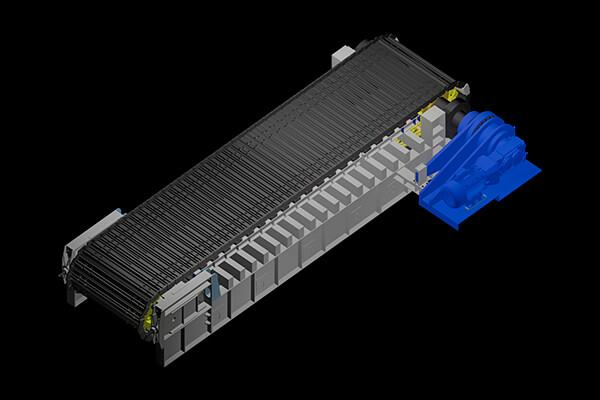

The no. 3 limestone crusher of Xinjiang cement factory adopts 2p℉-1212 type impact crusher for primary crushing, the feeding system adopts 1500× 12000

apron feeder, and the drag motor adopts y225m-4 three-phase ac asynchronous motor. Because apron feeder cannot adjust the linear speed of the system, when the feed is in excess, it can only stop the feeding by stopping the motor, which brings certain difficulties to the control of the feeding amount, especially in rainy weather, the material viscosity is large, and the motor starts and stops frequently under heavy load, which has a greater impact on the motor and transmission system. In addition, the interval feeding is not easy to control the uniformity of the feeding, which has a great impact on the particle size of the broken discharge, and is difficult to meet the production requirements.

2 System transformation and debugging

We use frequency conversion speed regulation technology to control the speed of apron feeder, that is, according to the principle of n=60, s, to achieve the speed p degree control of ac motor. Considering the requirements of the crushing system, the inverter can not only control the variable speed operation of the motor, but also provide sufficient torque output. To this end, among the many inverter brands, we choose the acs600 series inverter produced by abb, its main characteristics are as follows: 1) direct torque (dtc) control technology, changes the traditional vector inverter control mode, zero speed does not need speed feedback, can achieve full torque output characteristics, dynamic response is fast, and stable and controllable, starting torque up to 200% of rated torque, can withstand 150% overload for 1min. 2) to provide a full range of motor protection, including overvoltage, overcurrent, lack of phase and motor blocking and temperature rise protection, while realizing the soft start of the motor, so that the equipment runs smoothly, thereby extending the service life of the equipment, and can reduce vibration, impact and noise, provide a good working environment. Through the test, it is found that when the

apron feeder drive motor runs normally, the three-phase average current is only 30a(rated current 84.6a), and the motor selection is obviously large.

Frequency converter installation, wiring is relatively simple, under normal circumstances, just the frequency converter series connected to the main circuit cable of the motor can be. In order to facilitate operation, a 10k2 speed adjusting potentiometer and a digital display tachometer can be added to the operating table, and the original start-stop control loop does not need to be changed. Combined with the process status of the crushing system, in order to prevent the occurrence of adverse factors such as heating of motor windings caused by high harmonics during the no-load operation of subsequent crushing and low frequency operation, the lower limit of frequency is set at 10hz (speed 300r/min) and the upper limit is 50hz(speed 1470r/min). Adjust according to the actual needs of production.

3. Attack effect

1) Wide speed range feeding control to achieve stepless speed regulation, according to the actual incoming materials and subsequent crushing conditions can adjust the feeding amount in time, to achieve the expected effect of continuous and uniform feeding.

2) Motor starts no impact damage three-phase ac asynchronous motor using direct starting mode, the starting current is about 5 to 7 times the rated current. After the technical reform, the starting current is small, 1.7 times of the rated current, and the interval feeding mode of frequent start and stop of the motor is eliminated, the equipment operating condition is greatly improved, and the equipment maintenance workload of the post workers is reduced.