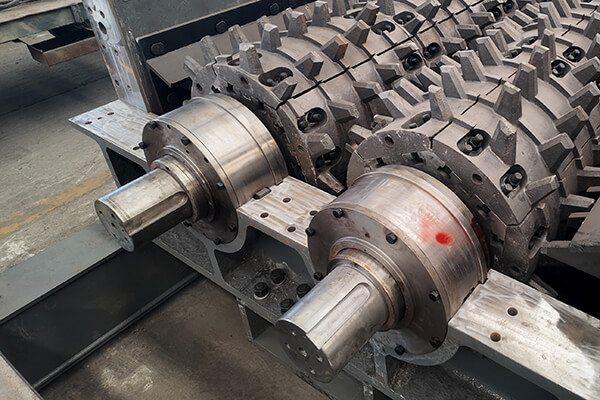

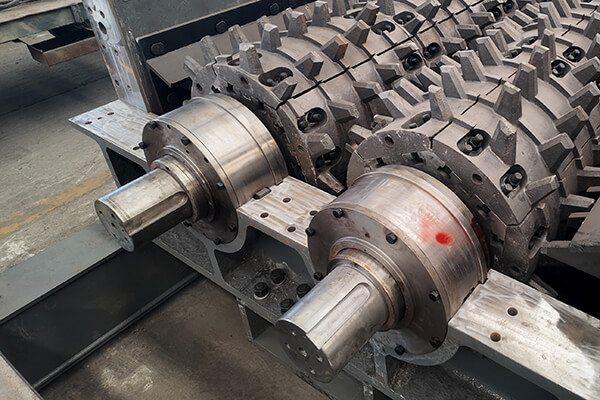

The Working Environment Of Mineral Sizer And Its Bearings

The Mineral Sizer is a device commonly used in industries such as mining and quarries, mainly for crushing minerals. During its operation, the bearings play a crucial role, supporting the rotating components of the equipment and ensuring its stable operation. The working environment of the Mineral Sizer is extremely harsh, with a large amount of dust, mineral particles and other impurities present. These impurities are prone to enter the bearing interior. Moreover, the equipment generates intense vibrations and impacts during operation, which impose extremely high requirements on the stability and durability of the bearings.

Reason For Bearing Wear Protection

Dust intrusion

The Mineral Sizer usually operates in environments such as mines and quarries, where the air is filled with a large amount of mineral dust. The dust is very fine and hard, and it can easily enter the bearing through the sealing gap of the bearing, forming abrasive wear between the rolling elements and the raceways of the bearing. During operation, it constantly scrapes and wears the bearing surface, accelerating the damage of the bearing.

Humidity and corrosion

In underground mines or during rainy weather, water will react with certain chemical components in the ore to form corrosive substances, which will cause corrosion to the metal surface of the bearing, damage the surface structure of the bearing, and reduce the strength and hardness of the bearing. Corrosion will also increase the roughness of the bearing surface, further exacerbating wear.

High-load operation

During the operation of the Mineral Sizer, large pieces of ore need to be crushed, and the bearing bears huge radial and axial loads. Long-term high-load operation will cause large contact stress between the rolling elements and the raceways of the bearing, leading to fatigue wear of the material. Fatigue wear will accumulate with the increase of operating time, causing peeling, cracks and other damages on the bearing surface.

Frequent impacts

When large or hard ore enters the crushing chamber, it will cause strong impacts on the components of the Mineral Sizer. The bearing will be subjected to instantaneous high stress, and frequent impacts will destroy the lubricating film of the bearing, causing the metal surface to come into direct contact, further exacerbating wear. At the same time, the impact may also lead to a decrease in the mating accuracy of the bearing, further affecting the normal operation of the bearing.

Long maintenance cycle

The Mineral Sizer is a continuous operation equipment. To ensure the continuity of production, its maintenance cycle is relatively long. During long-term operation, if the bearing does not have special wear protection, serious wear problems may occur within the maintenance cycle. Once the bearing fails, it may cause the entire crusher to stop, affecting the production progress and causing significant economic losses.

The Importance of Special Wear Protection

Improve reliability

By applying special wear protection to the bearings, the possibility of impurities entering the internal part of the bearings can be effectively reduced. Using a protective device with good sealing performance can prevent dust and mineral particles from invading, maintaining the cleanliness inside the bearings. At the same time, the special protective coating can enhance the hardness and wear resistance of the bearing surface, reducing the rate of wear.

Reduce maintenance costs

Special wear protection measures can extend the service life of the bearings and reduce the frequency of bearing replacement. This means that enterprises can save a significant amount of maintenance costs and downtime losses. Moreover, due to the improved reliability of the mineral sizer, the daily maintenance work will also be relatively reduced, lowering the workload and maintenance costs for maintenance personnel.

Enhance production efficiency

When the bearings receive good wear protection, the Mineral Sizer can always operate at an efficient level. It can accurately complete the crushing and screening tasks, improving product quality and production efficiency.

Common Special Wear Protection Measures

Sealing protection

Use high-quality seals. The seals can be selected according to different working environments and requirements, such as rubber seals and labyrinth seals, which can effectively prevent dust, moisture and other impurities from entering, protecting the lubricating grease inside the bearing from being contaminated and prolonging the service life of the bearing.

Lubrication protection

Choose the appropriate lubricant. The lubricant can form a protective film on the bearing surface, reducing direct contact between metals and lowering the friction coefficient. It can also remove the heat and impurities generated during the bearing's operation, playing a role in cooling and cleaning.

Surface protection

Special treatment of the bearing surface can increase its hardness and wear resistance. Common surface treatment methods include heat treatment, chemical plating, and coating.

Conclusion

In conclusion, implementing special wear protection on the bearings of the Mineral Sizer is extremely necessary. It can enhance the reliability of the equipment, reduce maintenance costs, increase production efficiency, and bring significant economic benefits to the enterprise. Enterprises should attach importance to the issue of bearing wear protection, select appropriate protective measures, and ensure that the Mineral Sizer can operate stably and continuously for a long time.