Composting

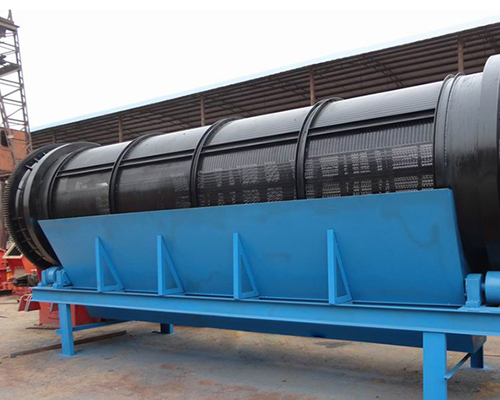

trommel screen is designed depend on the movement rule of materials in the trommel and the screening principle. It also combined with the specific requirements of composting production for screening equipment to design. However, there are some specific structure of the equipment should be improved.

1.The connection type of the sieving slice in trommel adopts the bolted connection. The type of connection complicates the replacement process. This paper will provide a connection type that convenient and quick and easy to replace the sieving slice. The type of mesh selected this time is perforated mesh, and the matching test of woven mesh can be set to verify the rationality of the selection of perforated mesh. In addition, for the selection of external screen material, the current market the metal material is widely used, It also has several new material screen mesh with wear-resistant, corrosion resistant and not easy to plug, such as polyurethane material screen mesh.

2.The roller used in this design is common iron core polyurethane caster. Because it used in the different application, the working performance and the service life is different.

3.

Trommel screen, the screening efficiency of roller cone Angle of the add and drop is low, this is because, with larger roller cone Angle, the content is single grain along the drum shaft line to advance speed is not broken, material contact with the roll barrel number don't reduce, because of the low down the probability of particles through the sieve, causing the screening efficiency, but it is important to note that on the one hand, in the mold to try to check, roller Angle smaller group, The total simulation time is several times that of the experimental group with a larger inclination, which means that when the same amount of materials are processed, although lowering the inclination of the drum can improve the screening efficiency, the screening time is greatly increased. On the other hand, in the actual production, the drum screen machine deals with continuous materials. When the inclination Angle of the drum is small, the movement of materials in the drum will become longer, which will lead to a large number of materials in the drum, but reduce the screening efficiency. Therefore, the influence of drum inclination factor on screening efficiency in this simulation test is not significant for the actual production guidance. The screening efficiency of the

trommel screen shows a trend of falling first and then rising with the increase of its rotating speed, but the range of its change is not large. In the actual working process of the drum sieving machine, the lower the speed of the drum, the higher its stability, and the less noise and vibration it produces. Therefore, a reasonable range of smaller rotating speed can be selected. Trend, the influence of the copy board copy plate set and whether the sieving efficiency of gigantic, motion state of grain in the drum can see out, not set copy board, the material particles motion amplitude is relatively small, and a low speed, and when the rolling cylinder is set with copy board, the material of the grain of the copy board, produce good 3 d effect, rate of particles contact with the screen surface is also more high, Because its screening efficiency is also higher, therefore, in the design of the roller screen sieving machine, the setting of the board is very necessary, and in the selection of the height of the board is not only from the simulation test results, but also from the economic aspects of consideration, the height of 6 0mm board is better than the height of 90 mm board.