The

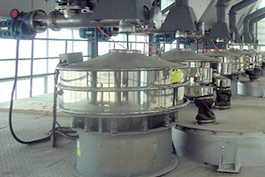

banana screen, also known as the multi-angle or multi-slope screen, adopts a banana-shaped multi-section screen surface design. Each layer of material on the screen has a high throughput, allowing for significant processing capacity within a relatively compact screening area. Banana screens are widely used in coal, mining operations, aggregate production, metallurgy, transportation, and the power industry. They are suitable for both dry and wet material screening.

Our company's banana screens mainly consist of the screen box, screen panels, vibrator, vibration-damping springs, drive unit, supporting frame, and lubrication system. The banana screen features multiple sections of screening surfaces, with the screen surface inclination gradually decreasing from the feed end to the discharge end.

During operation, the feed end—having a steeper inclination—allows materials to move quickly due to higher acceleration. This causes the material to stratify rapidly, allowing undersized particles to come into full contact with the screen and pass through efficiently. The discharge end has a gentler inclination, slowing material movement to ensure that any remaining undersized material has sufficient time to pass through the screen, significantly improving screening efficiency. The banana screen can meet specific application needs by adjusting the inclination of the multi-slope screen sections. The inclination angle directly influences material speed across the screen surface and the processing capacity of the banana screen.

Below are the proper methods for maintaining a banana screen.

I. Daily Operational Inspection

1.Pre-Startup Checks

Screen Surface Condition: Inspect the screen panels for any damage, looseness, deformation, or blockage. Pay particular attention to material buildup between screen holes, and promptly clean or replace damaged panels. Also check whether support beams and wear liners under the screen panels are loose or worn to ensure surface flatness.

Vibrating Components: Ensure the vibrator mounting bolts are tight to avoid loosening due to vibration during operation. Confirm that spring mounts are free from cracks or deformation and that the springs are functioning properly.

Feeding and Discharging Areas: Ensure that the feed and discharge chutes are free from blockages and that all connections are well sealed to avoid material leakage or impact damage to the screen surface.

2.In-Operation Monitoring

Vibration Parameters: Observe whether the equipment is vibrating smoothly and if the amplitude and frequency meet design specifications. Abnormal vibration may indicate loosened or unbalanced components. Listen for unusual noises such as knocking, friction, or motor anomalies—if detected, stop the machine immediately for inspection.

Motor and Bearing Temperatures: Use an infrared thermometer to check the temperature of the vibration motor and bearing housings. Temperature rise should not exceed 40°C, and the maximum allowable bearing temperature is 75°C. If overheating occurs, inspect lubrication or installation issues.

Screening Effectiveness: Check whether the feed material is evenly distributed across the screen to avoid local overloading due to uneven feeding. Inspect the discharge material for proper particle size—if oversized material remains after screening, the screen panels may be damaged or have insufficient open area.

3.Post-Shutdown Maintenance

After shutdown, clean any residual material from the screen surface and surrounding equipment—especially in the screen panel gaps and around the vibrator—to prevent corrosion and ensure smooth startup next time. Check all bolts on the

banana screen for tightness and re-tighten any that are loose.

II. Common Faults and Maintenance Solutions

Reduced Screening Efficiency: Likely due to clogged or worn screen panels—clean or replace as necessary.

Abnormal Noise: May result from loose bolts or damaged bearings—tighten bolts or replace bearings promptly.

Screen Misalignment : Often caused by failed damping springs or uneven installation—adjust leveling and replace springs.

Motor Overheating: May be due to insufficient lubrication or unstable voltage—re-lubricate and check power supply.

III. Periodic Cleaning and Lubrication Management

1.Equipment Cleaning

Daily Cleaning: After each shutdown, use compressed air or water to wash the screen surface, screen box, base, etc., to remove adhered material. Take care to avoid water entering the motor.

Periodic Rust Removal and Anti-Corrosion: At least once a year, remove rust from structural components such as the screen frame and supports, and apply anti-corrosion paint to prevent structural degradation.

2.Lubrication System Maintenance

In addition to the vibrator motor and bearings, other transmission components such as gears and sprockets should be lubricated periodically to ensure smooth operation. Keep detailed lubrication records, including time, location, lubricant type, and quantity, to prevent under- or over-lubrication.

From customer request to operational deployment, our company offers fully customized, end-to-end services for

banana screen projects. These include project design, installation and commissioning, mining operations, remote diagnostics, training, and a comprehensive maintenance program. Our maintenance plan is systematic, long-term, and well-rounded, ensuring your banana screen is well maintained and its service life extended. We also have a professional after-sales team to deliver high-quality support, ensuring that your project runs smoothly and continuously.

.jpg)