I. Definition

An

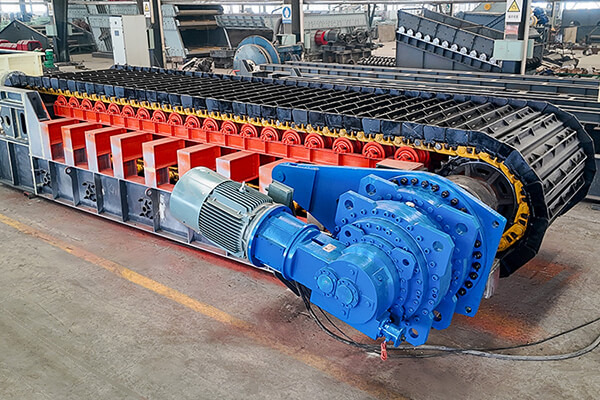

apron feeder is a reliable feeding method suitable for conveying blocky, abrasive, heavy, and high-temperature materials. It is a more robust and durable feeding solution than traditional belt feeders. Apron feeders are used in various applications that involve heavy loads and high-impact materials, delivering materials at a consistent rate to ensure optimal feed for downstream equipment.

A grizzly feeder is a device that integrates both feeding and pre-screening functions. It is typically used to feed bulk or granular materials evenly and continuously into crushing equipment, while simultaneously removing fine materials smaller than the bar spacing through the front-end grizzly bars. This enhances the efficiency and service life of downstream equipment.

II. Structural Design Differences

1.Load-bearing Components

The load-bearing part of an apron feeder consists of hundreds of overlapping steel pans connected together, often with wear-resistant liners. In contrast, a grizzly feeder features multiple parallel alloy steel bars, with adjustable spacing. The bar cross-sections may be round or rectangular, and surfaces may be hardfaced for wear resistance.

2.Drive Mechanism

An apron feeder is driven by a chain and sprocket system. A grizzly feeder is powered by a vibrating motor or an eccentric shaft.

3.Sealing

The apron feeder uses labyrinth seals between the pans and forms a continuous, enclosed conveying surface with no bottom leakage. This sealed structure prevents dust and fine material leakage. The grizzly feeder mounts bars at both ends on crossbeams of the side plates, supported in the middle to prevent sagging. It has no bottom plate, allowing fines to fall directly through to a conveyor or bin below. This open design makes it prone to fine material leakage.

4.Weight

Due to its heavy-duty pans and support structure, the apron feeder is significantly heavier. The grizzly feeder, using less steel, is lighter in weight.

III. Working Principle Differences

The

apron feeder moves material via chain-driven steel pans. A motor drives a reducer to lower speed and increase torque, which rotates the driving sprocket. This pulls the closed-loop chain and the attached pans in continuous motion. The pans form a consistent load-bearing surface that receives material (such as ore or coal) from the feed inlet and transports it along a horizontal or inclined frame (maximum inclination of 25°) to the discharge end, where material is offloaded by gravity or a discharge gate.

The grizzly feeder operates by generating vibrations through a motor or exciter with eccentric weights. This causes the feeder trough, fitted with grizzly bars, to vibrate at high frequency and low amplitude. Material jumps forward in a parabolic motion, while fine particles fall through the bar gaps. This realizes simultaneous feeding and pre-screening, making it suitable for large particle materials with a fine fraction.

IV. Functional and Application Differences

1.Core Function

The core function of the apron feeder is to feed the primary crusher continuously and evenly. It can also be used for short-distance transport of large, heavy materials. It is a pure feeding device without any screening function. The grizzly feeder, on the other hand, is designed for feeding coarse materials before primary crushing, with the added ability to pre-screen the material. It separates fines during the feeding process.

So, the key functional difference is that the apron feeder is dedicated solely to feeding, while the grizzly feeder combines feeding and pre-screening.

2.Suitable Materials

The apron feeder is suitable for blocky, abrasive, oversized, heavy, and high-temperature materials. The grizzly feeder is ideal for blocky or medium-to-large particles at normal or moderately high temperatures. It is not suitable for high-temperature materials; it can handle some abrasive materials but is less wear-resistant than an apron feeder. It is best used for medium-density and medium-weight materials such as ores, crushed stone, and coal.

3.Typical Application Scenarios

The

apron feeder is commonly used at the front end of primary crushing in metal mines, and for conveying cement clinker. The grizzly feeder is commonly used for aggregate screening and coal pre-screening.

The apron feeder's sealed chain-pan design is optimized for extreme heavy-duty environments, offering greater structural strength but at higher cost. The grizzly feeder's open-bar design supports dual feeding and screening but has limited load-bearing capacity.

In summary, the apron feeder is suited for heavy, high-hardness materials where stable, non-vibratory feeding is essential. The grizzly feeder is best for large materials with fine fractions, where pre-screening is required during feeding.

When selecting equipment, customers should consider the material characteristics, the need for screening functionality, and load requirements to make the optimal choice.

.jpg)

.jpg)

.jpg)