The

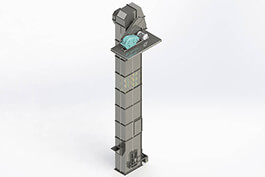

Z type bucket elevator is a continuous conveying device featuring a "Z"-shaped layout. This layout enables material to be fed horizontally, elevated at an inclined angle, and then discharged horizontally. The system is composed of a drive unit, pulleys, traction components, buckets, and an enclosure. Materials are fed into the elevator at the horizontal section, lifted through the inclined segment, and discharged from the outlet at the upper horizontal segment. This equipment is known for its small footprint, high efficiency, and excellent sealing performance. It is well-suited for granular and powder materials and is widely used in industries such as mining and construction materials.

I. Core Structural Components

The Z type bucket elevator mainly consists of the drive unit, traction system, and inlet/outlet components.

Drive Unit:

Comprises a motor, gearbox, and coupling. It drives the head pulley or sprocket to rotate, providing the traction force for the system.

Traction System:

Includes traction elements and buckets. The traction element can be either a rubber belt or chain, looped around the head and tail pulleys. Belts are suitable for light-load, low-speed applications, while chains are preferred for heavy-load, wear-resistant operations. Buckets are fixed to the traction element and typically made from carbon steel or stainless steel. Bucket shapes include shallow, deep, and triangular types. Shallow bucket is suitable for powdery materials, deep bucket is suitable for granular materials, and triangular bucket is suitable for large block materials.

Inlet and Outlet Devices:

The inlet is located at the beginning of the lower horizontal section, often equipped with a chute or feeder to ensure even material feeding.

The outlet is at the end of the upper horizontal section, where materials are discharged using centrifugal or gravity methods.

II. Working Principle

Horizontal Feeding: Materials are evenly fed into the buckets on the lower horizontal section via a feeder or chute.

Inclined Elevating: The drive unit moves the traction element, causing the buckets to ascend along the inclined segment, lifting the material to the head section.

Horizontal Discharge: At the head section, buckets turn into the horizontal discharge position. The material exits the bucket due to centrifugal force or gravity and is transferred to the next stage, such as a belt conveyor or storage bin.

III. Advantages

High Space Efficiency: The Z-shaped layout enables "horizontal + vertical + horizontal" conveying within a limited space. This solves the issue of traditional vertical elevators being unable to extend horizontally. It is ideal for environments with height restrictions or complex routing, reducing the overall footprint.

Dustproof and Sealed: The fully enclosed stainless steel housing effectively prevents dust from escaping, meeting environmental protection standards.

Wide Adaptability: It supports multiple inlets and outlets, flexible inclination angles, and can handle a wide range of material sizes—both powdery and blocky materials.

Easy Maintenance: Maintenance openings at the head section allow for easy inspection of bucket and traction wear. Some models support online tension adjustment.

IV. Differences from Traditional Vertical Bucket Elevators

Path Design:

Z type bucket elevator follows a zigzag "Z" shape, while traditional vertical bucket elevators have a straight vertical path.

Flexibility: Z type offers high flexibility with combined horizontal and vertical transport, while traditional types support only vertical movement.

Application Scenario: Z type is suitable for complex layouts needing horizontal integration, while traditional types are limited to vertical lifting.

Feeding/Discharging Method: Z type uses horizontal feeding and horizontal discharging; traditional types feed at the bottom and discharge vertically at the top.

V. Application Scenarios

Mining Industry: Used for lifting ore particles such as iron concentrate and limestone, typically from crushers to screens or storage bins.

Construction Materials: Transports cement, coal powder, sand, and aggregates—often used in vertical feeding sections of production lines like cement kilns.

Grain Processing: Lifts grains, flour, and feed. Stainless steel models are available to meet hygienic conveying requirements in storage and processing.

Chemical Industry: Transports fertilizers and chemical raw materials like urea and soda ash. Corrosion-resistant designs are available for harsh environments.

VI. Conclusion

The

Z type bucket elevator, with its innovative zigzag design, combines vertical lifting with horizontal conveying, making it an ideal solution for space-constrained settings. Its features—such as low material breakage, dust prevention, and support for multiple inlets/outlets—make it an indispensable piece of equipment across a wide range of industries.

With over 30 years of experience in bucket elevator design and manufacturing, our company can tailor professional solutions to your specific material characteristics, operational conditions, and project requirements.

.jpg)