Introduce

The three purposes of installing a secondary crushing device in mineral sizer - the crushing beam. On the one hand, enhance the efficiency of the entire crushing process. By installing a secondary crushing device, mineral sizer can achieve a finer and more consistent particle size distribution. On the other hand, the secondary crushing device helps to reduce the load on the primary crushing mechanism. It lessens the wear of the main components, thereby extending their service life and lowering maintenance costs. In addition, the crushing beam plays a crucial role in controlling the material flow direction through the mineral sizer. It ensures uniform distribution and orientation of materials, as well as excellent crushing performance.

Install secondary crushing devices in mineral sizer to enhance efficiency, reduce wear and tear, and improve the overall performance of the crushing process.

The current problems with mineral sizer

At present, the mineral sizer used for medium and fine grinding mainly has the following problems:

① The crushing ratio is small and the output particle size cannot be adjusted. The working principle of Mineral sizer is composed of two cross-arranged tooth profiles of toothed rollers, which determine the size of the output particle size in a three-dimensional space. When a smaller output particle size is required, the tooth profile is designed to be smaller, thus limiting the feed particle size from being too large. In addition, due to the presence of various uncertain factors in the on-site materials (such as moisture content, material strength, material size, etc.), it is easy for the particle size of the discharged materials to exceed the tolerance. The solution is to redesign the tooth plate. When the mineral sizer is used for a long time, the particle size of the output material may exceed the tolerance due to the wear of the tooth plate. At this time, the tooth plate also needs to be replaced. Due to the high price of the tooth plate, it increases the customer's usage cost.

② The fixing method of the tooth plate is unreliable. Due to the use of bolt connections, the bolts are repeatedly subjected to torsional and impact forces, leading to elongation and breakage. The detachment of the tooth plates can easily cause damage to the mineral sizer.

③ The material of the tooth plate is mostly high manganese steel, which has a limited service life and cannot be repaired after wear. Replacing the tooth plate is expensive.

④ As the gear roller and the reducer are often connected by a gear coupling, it generates a lot of noise and is inconvenient to maintain.

The design of the new Mineral sizer

Structure

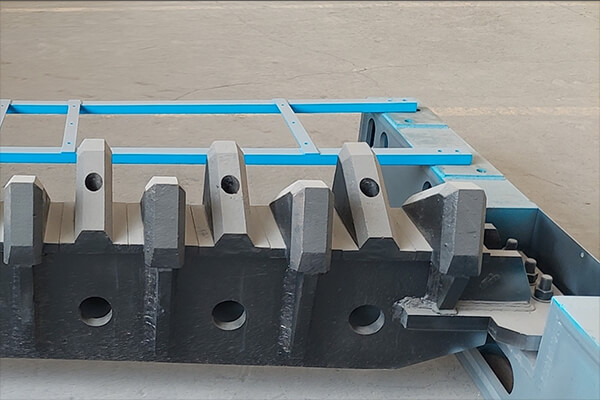

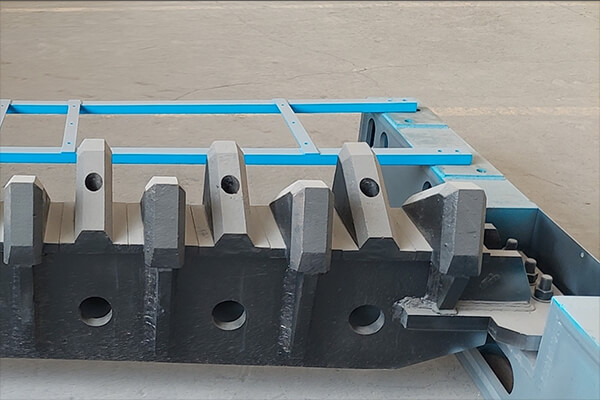

The new type of mineral sizer equipped with a secondary crushing device includes a base and a crushing system. A secondary crushing device crushing beam is installed below the crushing system, and an adjusting pad is set at the bottom of the crushing beam. The crushing system consists of two sets of toothed roller crushing units. Each set of toothed roller crushing units includes an electric motor, a hydraulic coupling, a reducer, an elastic pin coupling, a toothed roller and a toothed roller shaft. The electric motor is connected to the reducer through the hydraulic coupling, and the reducer drives the toothed roller shaft to rotate through the elastic pin coupling. The toothed roller is distributed with interlaced crushing teeth.

Toothed roller

The toothed roller consists of a toothed roller shaft, a toothed plate seat, a toothed plate, a round nut, a tensioning screw and a wedge. The toothed plate is fixed by the wedge tensioning method. The elastic pin coupling comprises a half coupling at the end of the gear roller shaft, a half coupling at the end of the reducer, an elastic body and a pin. Half couplings are installed at both ends of the reducer and the gear roller shaft. One end of the pin is mounted on the half coupling, and the other end is installed with the elastic body.

The gear roller of the new mineral sizer mainly consists of a gear roller shaft, a gear plate seat, a gear plate, a round nut, a tensioning screw and a wedge. The assembly method is to design a shaft shoulder at one end of the main shaft and a thread at the other end. After the gear plate seat is pressed onto the main shaft by a special device, it is locked with a double nut. The main shaft and the gear plate seat are connected by a flat key to transmit torque The fixation of the tooth plate and the tooth plate seat adopts a unique wedge block fixation method. The tensioning screw tensives the wedge block tightly against the tooth plate seat and the tooth plate. When the tooth plate crushes the material, the torsional force and impact force generated are transmitted to the tooth plate seat through the wedge block, avoiding the phenomenon of the screw being directly subjected to force and thus breaking. In addition, this fixing method of the wedge block also has the advantages of convenient installation, reliable fastening and quick disassembly.

Broken beam

The new type of mineral sizer solves the problems of small crushing ratio and adjustable output particle size by adding a secondary crushing device. It is driven by two motors to break the material with toothed rollers. The two toothed rollers rotate towards the center of the equipment, and the material is initially crushed by the shearing force and tensile force applied to the material through the interlaced and distributed crushing teeth on the toothed rollers. The toothed rollers drive the materials to act on the crushing beam, achieving re-crushing.

Due to the adoption of two-stage crushing, a larger tooth profile can be designed during the first-stage crushing to crush larger materials. The particle size of the output is controlled by the crushing beam of the secondary crushing device, which can achieve a larger crushing ratio. Under the crushing beam, there are spacers installed. By adjusting the height of the spacers, the particle size of the discharged material can be adjusted. When using mineral sizer, the height of the spacers can be adjusted according to the actual situation of the materials on site to achieve the required particle size of the materials. When the particle size of the discharged material increases due to the wear of the tooth plate, this method can also be adopted for adjustment, which improves the utilization rate of the tooth plate and reduces the usage cost.

Coupling

The elastic pin coupling of Mineral sizer is connected to the two halves of the coupling with pins. The pins are elastic, which can compensate for the relative displacement of the two shafts and also have the functions of buffering and shock absorption. At the same time, the elastic pin coupling also has the advantages of light weight, easy installation, low noise and maintenance-free.

Crushing ratio

The crushing ratio can be adjusted according to the actual material conditions on site to achieve the desired output particle size. The new mineral sizer wedge tensioning method for locking has solved the "falling tooth plate" phenomenon that occurs when the tooth plate is connected by bolts. It is easy to install and the connection is firm and reliable.

Tooth plate

The tooth plate is made of a new type of wear-resistant alloy material, which has a long service life. The motor and the reducer are connected by an elastic pin coupling, which can compensate for the displacement of the two shafts and also has the functions of buffering and shock absorption.

Summary

Compared with other crushers, this new type of mineral sizer, through long-term use in coal mines, has the advantages of strong ability to consume large pieces, low over-powder rate, uniform output particle size, safety and reliability, and few malfunctions.

.jpg)