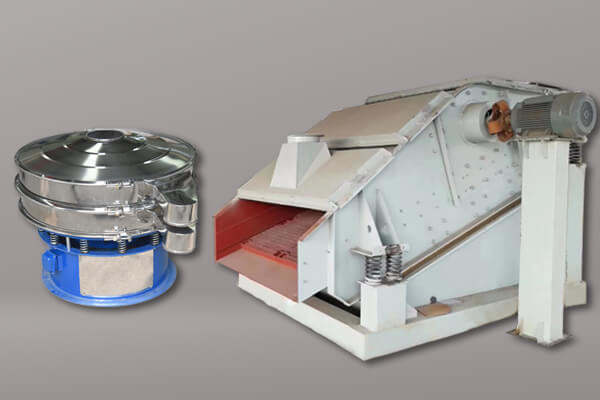

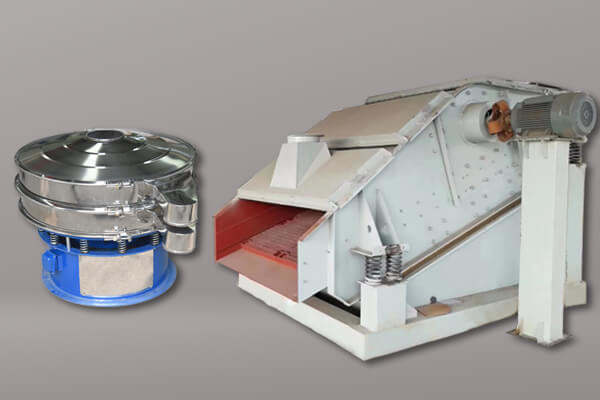

Vibratory separator and Circular vibrating screen, plus a vibrating screen, have a number of vibrating screens, such as vibrating screen, plus a vibrating screen, plus a vibrating screen.In China, because of their diverse shape, many manufacturers call vibratory separator "circular sieve," circular vibrating screen, but in fact the two vibratory pumps are truly distinct products.

Let us begin with a circular vibrating screen, which is a vibrating, mufti-layer, highly effective new vibrating screen.Circular vibrating screen with cylinder postures eccentric shaft vibrator and eccentric block to adjust the amplitude, material sieve drip line length, screening specifications, is reliable in structure, strong exciting force, high screening efficiency, vibration noise is small, strong and durable, easy maintenance, use safety, etc, the vibrating screen is widely used in mining, building materials, transportation, energy, chemical and other industries products classification.Usually, circular vibrating screen, plus a handful, is more commonly used in mines, such as a large amount of materials, plus a large amount of processing, noise, and fast processing.A circular vibrating screen usually has a relatively high price.

A vibrating screen, plus a vibrating screen, is vibrating, plus a vibrating screen, plus a vibrating screen, vibrating or vibrating, plus a vibrating screen, vibrating or vibrating.Resonance screen once rose, was widely valued and developed rapidly;However, in production practice, the disadvantages such as complex structure, difficult adjustment and many faults are exposed.Moreover, inertial vibrating screen, plus simple structure, reliable operation, and convenient maintenance, has been widely used.An inertial vibrating screen, plus a vibrating screen, is driven by an inertial vibrator with an eccentric block, vibrating the screen.In the form of a vibrator, an inertial vibrating screen can be vibrating either a single-axis vibrating screen or a double-axis vibrating screen.

In accordance with the characteristics of motion track of a vibrating screen, a vibrating screen has been divided into a circular vibrating screen, plus a linear vibrating screen, plus a vibrating screen.A Circular vibrating screen, due to a deviation in the position of the vibrator, is generally ellipse Circular.Even a linear vibrating screen, due to manufacturing and design distortion

In general, the screen box is not completely linear motion trajectory, just close to the linear vibration.Since a circular vibrating screen is a vibrating axis, it is also called a single-axis vibrating screen, plus a linear vibrating screen, plus a vibrating two-axis vibrating screen, plus a vibrating linear vibrating screen, plus a vibrating two-axis vibrating screen.

Circular vibrating Screen consists of a sieve box, sieve, vibrator, and vibration absorbent spring.If there is no special requirement, YA and 2YA for textile screen surface, YAH for punching screen surface, all kinds of screen surface can meet.

A vibrating screen, plus a vibrating screen, consists of a sieve box, sieve, vibrator, vibration damping spring device, under-frame, suspension (or supporting) device, and motor.

YKX circular vibrating Screen structure: It consists of a spring supporting set, a transmission device, a screen box, a supporting seat, and a thin oil lubricating vibrator.

The drive screen adopts disc coupling and flexible disc coupling with simple structure and easy manufacture and maintenance, which overcomes the defect of universal coupling.The vibrator adopts eccentric structure, which is simple in structure.Optionally, a feeding box can be used to add a vibrating screen, plus a vibrating screen's effective screening area, plus a vibrating screen's lifetime at the feeding end.In the transmission part, the intermediate transition bearing pedestal is added. The application of the intermediate transition bearing pedestal can effectively protect the motor and extend its service life.The motor can be installed on the left side of the screen frame or on the right side of the screen frame.This series of screen is mounted on a seat.The tilt of screen surface can be adjusted by changing the height of spring support

Vibratory separator is high precision fine powder sifting machine with low noise and high efficiency. It takes 3-5 minutes to quickly change the net. Vibratory separator is fully closed structure, suitable for sifting and filtering materials such as granules, powders and mucilage.Vibratory separator is high precision fine powder sifting machine with low noise and high efficiency. It takes 3-5 minutes to quickly change the net. Vibratory separator is fully closed structure, suitable for sifting and filtering materials such as granules, powders and mucilage.Vibratory separator is motivated by an upright motor with a eccentric hammer on the upper and lower ends. The motor's rotational motion is converted into a horizontal, vertical and slanting three-dimensional motion which is then transmitted to the sieve surface.By adjusting the phase Angle of upper and lower ends, the motion trajectory of material on the screen can be changed.

Vibratory separator is vibrating source of upright motor, and the upper and lower ends of the motor are equipped with a eccentric hammer, which changes the motor's rotational motion into a horizontal, vertical, and tilted three-degree motion. Then, the motion is transferred to the screen surface to make the material perform a vibrating progressive movement on the screen surface. Therefore, such a series of vibrating screen is called a vibrating screen, plus a vibrating screen, plus a vibrating screen, plus a vibrating screen, plus a vibrating screen, plus a vibrating vibrating screen.Vibratory separator has the advantages of long track running of material and high screen surface utilization. Adjusting the phase Angle of the upper and lower end weights can change the motion track of material on the screen.Can carry on fine screen to material, probability screen etc.

Vibratory separator, after starting the power unit that is both ends up and down the different phase of eccentric block vibration motor, due to the high speed placement and produce a compound inertia force, the force of inertia force vibration sieve machine body for the complex spinning movement, under the action of vibration sieve box continuous reciprocating movement, periodic vibrations into the ground and drive the screen surface, so that the material on the surface of the screen to make directional movement enthusiastically with screen box, meanwhile, less than the material through the screen mesh of screen surface aperture to lower level, becoming the under-size, greater than the screen surface pore size of the material after continuous jumping movement from the discharging mouth deduction, eventually completed screening work.The track of

vibratory separator is a complex three-dimensional spatial curve, which is circular in the projection on the horizontal plane and ellipse circular in the vertical plane.In practical application, by adjusting the relative phase of the eccentric blocks at the upper and lower ends of the vibration motor, the motion track of the material on the screen surface can be changed, so as to achieve different purposes of screening.

Through the above comparison, we found that these are two completely different screening equipment, working principle, use is completely different, so do not confuse, our EXCT is a specialized manufacturer of screening equipment, we will design reasonable technical solutions according to your needs, to provide you with suitable products.We have been adhering to the customer first, quality first service purpose.In the future we look forward to working with you to achieve a win-win situation.