I. Definition

The

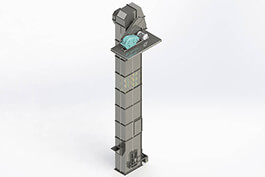

Z type bucket elevator is a conveying device named for its “Z” shaped conveying path. It consists of buckets, traction components, and other parts. Material enters through the inlet at the bottom, is lifted via buckets along an inclined section, and is then discharged at the outlet after the top turning into a horizontal section. The Z type bucket elevator is suitable for gently transporting a wide range of free-flowing bulk materials under dry, semi-dry, or moist conditions. This equipment offers strong adaptability and can transport materials from one or multiple sources to multiple destinations through various discharge positions and stations.

II. Core Components and Their Functions

The Z type bucket elevator primarily consists of the drive unit, chains, sprockets, buckets, and tensioning device.

1.Driving Device

The driving device includes a motor, a reducer, and a coupling, which are used to drive the active roller or sprocket to rotate and provide traction power. We have long cooperated with famous international brand, such as SEW, Siemens, also with some domestic brand, such as YUTONG, TaiLong, internation trade. The motor has long service life, steady operation, save energy and environment protection.

2.Chain

The Z type bucket elevator uses chains made of high-quality alloy steel to ensure strength. The chains have a simple structure, good wear resistance, reliable operation, easy assembly and disassembly, flexible transmission, and low operating noise.

3.Sprockets

The sprockets used in the Z type bucket elevator are made of alloy steel or stainless steel. These sprockets offer high strength, strong engagement with the chain, excellent wear resistance, long service life, and are easy to install and replace.

4.Buckets

Our company can customize buckets according to customer requirements, with materials such as ABS, high-quality stainless steel, or regular carbon steel. The buckets offer features such as heat resistance, corrosion resistance, flame retardancy, high strength, good flowability, and non-stick properties. The bucket’s function is to carry material, and the material should be selected based on the characteristics of the conveyed substance.

5.Tensioning Device

Our

Z type bucket elevator uses a screw tensioning device to adjust the chain’s tension. This effectively prevents chain slippage or derailment and avoids breakage from over-tightening. The tensioning device has a simple structure and is easy to adjust.

III. Working Principle

The Z type bucket elevator is used to elevate various materials to a designated conveying height. Buckets are suspended on a continuous hollow chain, which is driven by a geared motor installed on the top horizontal arm, located outside the steel casing. The material inlet is located on the lower horizontal arm and consists of a vibrating feeder and brush device to ensure steady, continuous feeding into the buckets. The elevator is equipped with maintenance access ports for easy servicing and cleaning, as well as a drawer at the bottom for cleanup.The detailed working principle is as follows:

1.Feeding Stage

Material enters the elevator through the inlet located at the bottom or horizontal section and is received by the buckets. Feeding can be via gravity or forced feeding. Gravity feeding is suitable for materials with good flowability, while forced feeding is for fine, dusty, or poorly flowing materials. Buckets remain upright during the horizontal section to ensure stable loading.

2.Lifting Stage

Buckets fixed on the chain are driven along a sealed track by the drive unit. During the inclined or vertical lifting phase, the buckets move upward. Gravity causes the material to press against the rear wall of the bucket, preventing spillage and ensuring stable conveying. The fully enclosed design prevents dust leakage, making the system suitable for environments with strict environmental standards.

3.Discharging Stage

As the bucket reaches the top curved rail, it flips due to the change in direction. The material is discharged from the outlet either by gravity or centrifugal force, depending on the operating speed.

Centrifugal discharge is used for dry, free-flowing materials, where the high-speed motion creates centrifugal force to eject the material.Gravity discharge is suitable for slow-speed operation and is ideal for moist or sticky materials, where material naturally falls out as the bucket rotates into the horizontal section.

4.Return Stage

After discharging, the empty buckets of the

z type bucket elevator travel downward along the opposite side of the track to return to the feeding point, completing one full cycle. Some models support multiple feed and discharge points to meet complex process requirements.