3. The crushing box of the

mineral sizers general structure is assembled by steel plate, using type 80 channel steel as the base of the equipment. The bottom seat of the crushing box is connected by bolts, and a certain fastening device is adopted after the bolts are tightened. In the design, all parts of mineral sizers will be optimized as a whole, and the reduction mechanism and the crushing box will be made into an integrated form, which will improve the integrity and also improve the sealing. The gear shaft is adopted in the form of semi-exposed gear shaft, and the upper cover and semi-exposed part are well sealed.

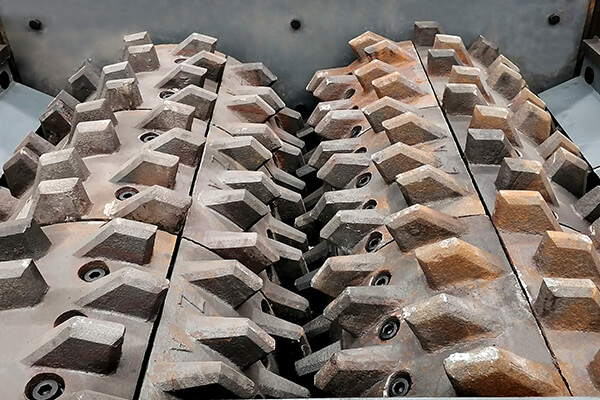

4. In mineral sizers, different tooth shapes and tooth layout schemes can obtain different crushing effects. There are mainly the following schemes for the setting of tooth shapes and tooth layout:

(1) Cone teeth are selected on the surface of mineral sizers roller teeth, and the edge on one of the roller teeth forms a convex circular groove, which forms concentric circles with the outer circle of the gear roller of the equipment. On the surface of the tooth roll, a rectangular lattice with equal spacing is selected for tooth layout, which can obtain the crushing material close to the cube. The teeth of another tooth in the double-toothed roll are opposite the center of the diamond, and the maximum particle size of the broken material is mainly determined by the distance between the top of the tooth in the matching double-toothed roll and the surface of the other roll. (2)

mineral sizers medium roll tooth profile is a corrugated tooth scheme, by inserting every 4 roll teeth on a tooth sleeve, the tooth sleeve and the wheel ring are connected by screws. The wheel ring is square, and the alloy blade is installed with screws at the part where the roller teeth cut the material and the material, and the roller teeth are arranged in a spiral shape. This arrangement is different from the traditional way of meshing and crushing between the roller teeth and the roller surface. A series of crushing teeth are connected into a spiral shape through the key and the shaft, and the crushing of the material is completed through the rolling between the teeth. (3) The tooth shape and layout scheme of the two roller teeth are the same, and the roller teeth of this arrangement scheme are mainly composed of the mandrel and the crushing teeth, the crushing teeth are connected with the mandrel through the key, and the spiral arrangement of the crushing teeth on the mandrel is realized by adjusting the Angle of the key way of the crushing teeth. In the first scheme of the above three schemes, the shape and configuration of the roller teeth effectively reduce the phenomenon of over-crushing. Compared with the ordinary configuration of the roller teeth with edge teeth, the configuration of the first scheme will obtain more uniform particle size. In addition, plan one stress? Uniform will effectively enhance the service life and efficiency of mineral sizers. Scheme 2 adopts a different tooth shape and configuration design from scheme 1, which mainly relies on the rolling of teeth to break materials, which is more efficient than the traditional crushing form of roll face to roll teeth. Meanwhile, the cemented carbide blade used in scheme 2 as the roll teeth will make mineral sizers more crushing. When the crushing teeth wear is more serious, only the blade can be replaced, which improves the use efficiency of the equipment. The screw arrangement of the crushing teeth on the mandrel can be realized by changing the Angle of the keyway on the crushing teeth, which can realize the crushing effect of the second scheme and simplify the connection structure effectively. Of the above three mineral sizers roll profile and configuration schemes, Scheme 3 effectively combines the advantages of Scheme 1 and Scheme 2 and greatly improves both crushing efficiency and crushing effect. Therefore, Scheme 3 is chosen as the

mineral sizers roll profile and configuration design.