Introduce

Mineral sizer is widely used in coal preparation plants and open-pit mines because of its working principle, which can effectively reduce excessive crushing of fine materials and improve crushing efficiency. The working environment of Mineral sizer is usually very harsh. The drum gear coupling is used to connect the reducer and the toothed roller group. The teeth of the drum gear coupling are prone to wear. The following will specifically analyze the faults of the drum gear coupling in Mineral sizer in combination with the working principle of the drum gear coupling and its application in Mineral sizer.

The structure of the gear coupling

A coupling is a device that connects two shafts or a shaft and a rotating part, rotating together during the transmission of motion and power, and does not disengage under normal circumstances.

lInternal gear ring

The internal gear ring is equipped with a tooth shape that meshes with the external gear.

lExternal gear sleeve

The tooth tip of the external gear sleeve is made in a drum shape, and the tooth surface is arc-shaped, which is a feature that distinguishes it from other gear couplings. The design of the drum-shaped teeth enables the tooth surface to better adapt to the relative displacement of the shaft during meshing.

lEnd cover

It is used to fix and protect the internal components of the coupling, ensuring stable operation.

lSealing device

It effectively prevents dust, impurities, etc. from entering the interior of the coupling.

Working principle of the drum-shaped toothed coupling

The working principle of the drum-shaped toothed coupling is based on its special drum-shaped tooth design and meshing principle. When the two shafts have relative angular displacement, the tooth surfaces of the inner and outer teeth will periodically undergo axial relative sliding. This sliding enables the coupling to adapt to certain angular, radial and axial displacement compensation.

lTorque transmission

The torque of the driving shaft is transmitted through the outer tooth sleeve to the inner tooth ring, which then drives the driven shaft to rotate.

lDisplacement compensation

The drum-shaped toothed coupling has the ability to compensate for axial, radial and angular deviations of the axis.

lLubrication

The lubrication system is used to reduce tooth surface wear and extend the service life.

Application of the Drum-shaped Toothed Coupling in Mineral Sizer

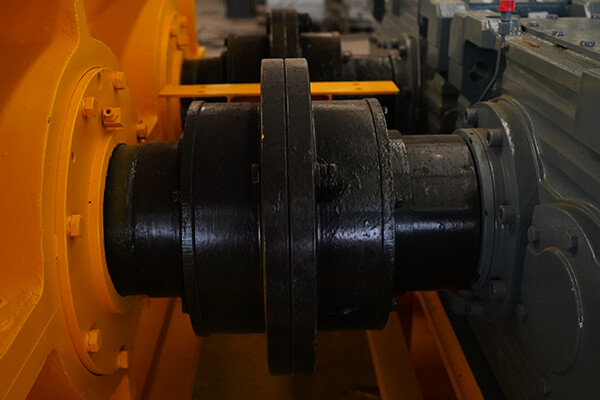

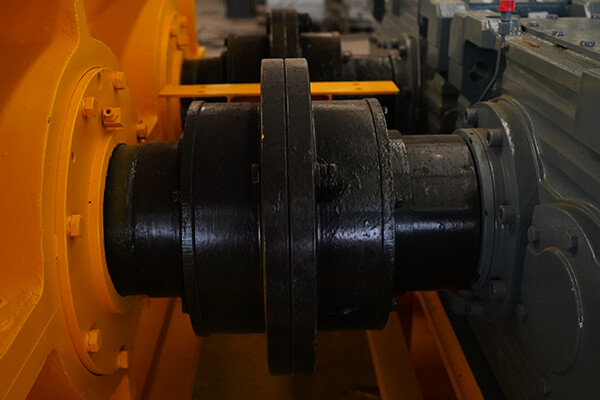

Position and Linking Method

In the mineral sizer, the drum-shaped toothed coupling is usually installed between the reducer motor and the crushing toothed rollers, serving to transmit torque and adapt to displacement changes. The linking methods mostly adopt flange connection or key connection to ensure the stability of the connection between the coupling and the reducer, as well as the crushing rollers.

Function and Effects

ⅰ. In the mineral sizer, the drum-shaped toothed coupling links the reducer and the crushing toothed roller assembly. During the crushing process, the contact points between the tooth surfaces of the coupling will change with the relative displacement of the shaft, and the mineral sizer can operate stably even when crushing hard materials.

ⅱ. When the two crushing shafts have relative displacement due to installation errors, non-coincidence of the axis, or changes in working load, the tooth surfaces of the drum-shaped teeth can flexibly adapt, ensuring the stable operation of the mineral sizer.

ⅲ. The coupling is equipped with safety pins, providing overload protection to prevent the mineral sizer from bearing excessive loads during operation.

Fault causes of the drum-shaped toothed coupling

Seal failure

During operation, the two shafts of the drum-shaped toothed coupling will have relative angular displacement, and the tooth surfaces of the inner and outer teeth will undergo periodic axial relative sliding, which will inevitably lead to tooth surface wear and power consumption. It is necessary to operate under a good sealing condition. The Mineral Sizer operates for an extremely long time, and the seal of the coupling is damaged by dust, with impurities inside. As the tooth surfaces slide relative to each other, the impurities will continuously grind the tooth surfaces, accelerating the wear process of the tooth surfaces.

Torque overload

The coupling can transmit torque. However, during the crushing process of the Mineral Sizer, a torque exceeding the design carrying capacity is generated, causing the transmitted torque to exceed the rated torque of the coupling, which will result in excessive pressure on the tooth surfaces, accelerating the fatigue damage of the tooth surfaces, and causing peeling, cracks, and other failure forms.

Insufficient lubrication

During the actual operation of the Mineral Sizer, due to the harsh working environment and large amount of dust, the lubricating oil may be contaminated, or the lubrication system may fail, resulting in insufficient lubrication. The friction between the tooth surfaces will increase, generating excessive heat, accelerating the wear and fatigue damage of the tooth surfaces, and causing coupling faults.

Denting and cracks on the tooth surface

Under long-term load action, the tooth surfaces will undergo local denting. In severe cases, cracks may even form. This will significantly reduce the carrying capacity of the coupling; if not handled in time, it may lead to more serious faults of the Mineral Sizer.

.jpg)