I. Definition

The

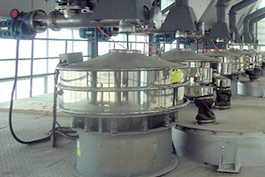

banana screen is also called a multi-angle screen or a multi-slope screen. It adopts banana-shaped multi-segment screen surface technology. Each layer of screened materials has a large throughput, and a large throughput can be achieved in a relatively small screening area. Banana screens are used in coal, mining operations, aggregate production, metallurgy, transportation, and power industries, and are suitable for dry and wet screening of materials.

II. Components

The banana screen is mainly composed of a screen box, a screen plate, an exciter, a vibration damping spring, a drive device, a support frame, a lubrication system, etc.

The banana screen adopts a multi-slope screen surface, with a large processing capacity and high screening efficiency. The banana screen is composed of multiple sections of screen surface, and the inclination angle of the screen surface gradually decreases from the feed end to the discharge end.

Frame side panel: The frame side panel is made of high-quality low-alloy high-strength structural steel plate, and a high-precision laser cutting machine is used to complete the feeding and drilling of the entire steel plate at one time, without splicing, and the appearance is flat and beautiful. In the area where the side plate is subjected to greater force, reinforcing plates, protective plates, and reinforcing angle steels are reasonably arranged, which effectively increases the strength of the side plate, makes the force of the side plate evenly distributed, and prevents elastic deformation.

Crossbeam and exciter base beam: The banana screen crossbeam is a rectangular hollow structure with high rigidity and light weight, and completely eliminates the vertical splicing. This structural design has a high safety factor and is suitable for complex working conditions. The exciter bottom beam plays a vital role in the operation of the banana screen. It adopts a box-shaped section design and is equipped with a reinforcing plate with high rigidity and light weight. The special design of the reinforced flange can effectively improve the strength of the banana screen.

Exciter: The exciter adopts the ZYQX series high-efficiency gear-driven thin oil-lubricated box-type exciter independently developed and manufactured by our company, and is equipped with imported SKF large-clearance vibration machinery special bearings. The specially designed special sealing structure of the shaft end can ensure that dust or other foreign matter cannot enter the interior of the exciter. The eccentric torque of the exciter eccentric wheel is adjustable to meet the different amplitude requirements of the equipment for the material.

Damping spring: The banana screen uses steel cylindrical spiral compression spring for shock absorption, and is designed with special parameters. It has large bearing capacity, long service life, and excellent shock absorption effect.

Screen plate: The screen plate adopts foreign advanced technology, modular design, high universality, and the screen plates between different models are completely interchangeable. It is fixed with polyurethane slots, which is easy to install and disassemble. Polyurethane side strips and polyurethane wedges are installed on both sides of the screen plate to fix the screen plate, effectively preventing the material from wearing the side plate of the screen machine and extending the service life of the screen frame.

III. Working principle

Structure and movement characteristics:

When the

banana screen is running, the screen surface at the feed end has a large inclination angle, and the material entering the screen surface moves forward rapidly with a large acceleration and quickly stratifies. The material smaller than the screen hole is fully in contact with the screen surface and passes through the screen smoothly.

The screen surface at the discharge end has a gentle inclination angle, and the material movement speed gradually slows down, so that the remaining material smaller than the screen hole can fully pass through the screen, greatly improving the screening efficiency.

The banana screen can meet specific application requirements by changing the inclination angle of the multi-slope screen surface. The inclination angle of the multi-slope screen determines the running speed of the material on the screen surface and the processing capacity of the banana screen.

Working principle core mechanism:

1. Material stratification and screening

After the material enters the screen surface from the feed end, it quickly forms a loose material layer under the action of vibration. The fine particles with higher density sink to the screen surface due to gravity, while the coarse particles with lower density float on the upper layer (i.e. "stratification by density").

The inclination angle and vibration parameters of the screen surface give fine particles more opportunities to contact the screen holes and penetrate the screen, while the coarse particles gradually move along the screen surface to the discharge end and are finally discharged from the end.

2. Multi-stage screening enhances efficiency

Feed end (large angle section): The initial material speed is fast, and the large angle design allows the material to move forward quickly and be initially stratified, which is suitable for processing high moisture content or sticky materials and reducing the risk of blockage.

Middle section (angle decreasing): The material speed gradually decreases, the stratification effect is further optimized, the fine particles continue to penetrate the screen, and the coarse particles continue to move forward.

Discharge end (small angle section): When the material approaches the end of the screen surface, the speed is the slowest, the fine particles can fully pass through the screen, and the coarse particles (screened materials) are effectively discharged, ensuring the screening accuracy.

3. Advantages of handling difficult materials

The curved screen surface and strong vibration characteristics of the banana screen make it particularly suitable for handling wet, sticky or high-fine particle content materials (such as coal slime, ore pulp, wet sand, etc.).

The vibration effect can destroy the cohesion of the material and prevent the sieve holes from being blocked, while extending the residence time of the material on the screen surface and improving the screening rate.

IV. Features and advantages

The banana screen adopts banana-shaped multi-segment screen surface technology. Compared with similar screening equipment, it has higher screening efficiency and smaller footprint.

The core advantages of the banana screen can be seen from the following aspects.

1. Multi-angle screen surface design: large inclination angle in the front section (quick discharge of fine particles) + small inclination angle in the back section (extending the screening time of coarse particles), improving screening efficiency and processing capacity.

2. Low failure rate: It uses a block eccentric vibrator with stable vibration parameters, which is suitable for processing wet and sticky materials (such as wet coal and clay) and is not easy to block holes.

3. Compact structure: It takes up little space and can be integrated into the production line to achieve continuous operation, especially suitable for scenes with limited space.

V. Conclusion

Our company has skilled technical workers and a complete quality management system to ensure the high performance and high quality of the

banana screen. Our comprehensive service portfolio is supported by experienced technical engineers and professional tools to maximize your profitability. From customer requirements to project operation, we can tailor a full range of services for your project, including project design, equipment manufacturing and procurement, installation and commissioning, and mine operation.

.jpg)

.jpg)