I. Definition

The

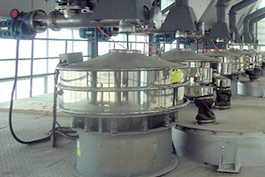

banana screen, also known as a multi-angle or multi-slope screen, adopts banana-shaped multi-stage screen surface technology. Each layer of material screening allows a large throughput, enabling high capacity within a relatively compact screening area. Due to its high screening efficiency, the banana screen is widely used in the mining industry.

II. Core Components

A banana screen mainly consists of a screen box, screen panels, exciter, damping springs, drive unit, supporting frame, and lubrication system. The key components—exciter, screen panels, and damping springs—are detailed below:

1.Exciter

The exciter uses our independently developed ZYQX series high-efficiency gear-driven oil-lubricated box-type exciter, equipped with imported SKF large-clearance vibration-specialized bearings. The specially designed shaft-end seal structure ensures that dust or other foreign particles cannot enter the exciter. The eccentric torque of the exciter’s counterweight can be adjusted to meet varying material vibration amplitude requirements.

2.Screen Panels

The screen panels use advanced foreign technology with a modular design, ensuring high interchangeability between different screen models. They are mounted using polyurethane slot clamps for easy installation and removal. Polyurethane side strips and wedges are installed on both sides of the panels to secure them, effectively preventing material from wearing the screen box sidewalls and prolonging the screen frame's lifespan.

3.Damping Springs

The banana screen employs steel cylindrical helical compression springs, designed with special parameters. These springs provide high load capacity, long service life, and excellent shock absorption.

III. Working Principle

The

banana screen features a multi-slope screen surface, resulting in high processing capacity and screening efficiency. It consists of several screen sections, with the screen angle gradually decreasing from the feed end to the discharge end. During operation, the material enters the feed end where the steep angle allows it to rapidly move forward and stratify due to the high acceleration. Fine particles pass through the screen quickly. At the discharge end, the gentler angle slows material movement, allowing remaining undersized particles more time to pass through the screen mesh, thereby improving screening efficiency. The inclination of the multi-slope screen surface can be adjusted to meet specific application requirements in mining. The slope angle determines the speed of material movement and the banana screen’s processing capacity.

IV. Specific Application Scenarios

In the Coal Industry:

1.Raw Coal Grading and Screening

Application: The banana screen classifies raw coal into different size fractions such as lump coal, medium coal, and fine coal to meet the needs of various users like power plants and coking plants.

Features:

The banana-shaped curved screen surface with large-to-small inclination allows fast transport in the front section and extended screening time in the rear section. This improves the screening efficiency of fine particles. It can handle high-moisture raw coal and sticky materials with a wide particle size distribution, reducing screen hole clogging.

2.Coal Slime Dewatering

Application: In coal preparation or washing plants, banana screens are used for dewatering fine coal concentrates after flotation, removing excess water or media, and lowering product moisture content for easier transport and storage.

Features:

The combination of vibration and sloped screen surface enables fast dewatering. Moisture content after screening can be reduced to below 15%. With high throughput, it is suitable for large-scale coal slurry processing systems.

In the Metal Mining Industry:

1.Ore Classification

In the crushing and screening stages of iron ore, copper ore, and other metal mines, banana screens are used to classify the crushed material and control the feed size for the next processing stage.

2.Pre-screening of Crushed Material

After secondary or tertiary crushing, banana screens separate oversized material for re-crushing and allow undersized particles to proceed, thus reducing the grinding load.

3.Final Concentrate Screening

After flotation or magnetic separation, banana screens are used for final sizing of concentrates to ensure particle size meets product standards. Applicable to iron, copper, lead-zinc, and gold ores.

4.Tailings Dry Discharge

Banana screens dewater tailings slurry after beneficiation, reducing tailings pond pressure and supporting environmentally friendly discharge or tailings reuse.

V. Technical Advantages

Our company’s

banana screens adopt banana-shaped multi-stage screen technology, providing higher screening efficiency and a smaller footprint compared to similar equipment.

1.High Screening Efficiency

The multi-stage screen panels promote smooth material discharge, reduce blockage, and significantly improve screening efficiency.

2.Multiple Screen Panel Options

A variety of panel materials are available, such as woven wedge wire, polyurethane modular panels, and rubber modular panels, to meet different screening needs.

3.High Strength and Rigidity

The main beam of the exciter and the crossbeams of the screen frame use box-beam structures with internal reinforcements, enhancing the machine’s rigidity and strength while reducing weight—thus improving efficiency and lowering energy consumption.

.jpg)

.jpg)