Since July, the high temperature in the northern region has been continuously breaking records. Our factory has strengthened production management, improved workshop environment by adding high-power air conditioning fans in the workshop, and improved workers' working comfort. Our workshop has been working overtime and in full swing, and recently our major projects have entered the final stage.

The first is our

Sidewall Belt Conveyor project in Vietnam, which was our customer last year. The customer find us through our official website and sent inquiry to us. After several rounds of communication, our professional skills and good service were recognized by the customer. Finally, the customer placed an order with our company at the end of July this year. However, due to the intermediate technical communication and the repeated modification of the scheme by the client, the production period is short and the task is heavy. Therefore, we set up a professional project team to keep an eye on the project progress and ensure the quality of the product. Recently, after more than a month of intensive production, Sidewall Belt Belt conveyor has been practically completed, and has been accepted by our professional quality inspection department. The products are qualified and meet the factory requirements. Delivery arrangements will be completed early this month.

Vietnam's sugar refinery project is a capacity of up to 60 t/h refined sugar production line, we are mainly responsible for production 11 of sets of

belt conveyor, customers communicate with us, through the remote communication, video meeting, customer just decided to cooperate with us only in 7 days time, made the advance payment, this is the recognition of our technical solution, is also a recognition of our service. In order to finish the production on time, our workers work overtime and cooperate with each other. Recently, we have completed the production of product frame, accessory roller and pulley as well as the procurement of SEW reducer motor. At present, we specially invite our quality inspection department to carry out quality inspection on the belt conveyor. At present, the quality inspection has reached the standard of delivery and the conveyor will be completed in the middle of this month.

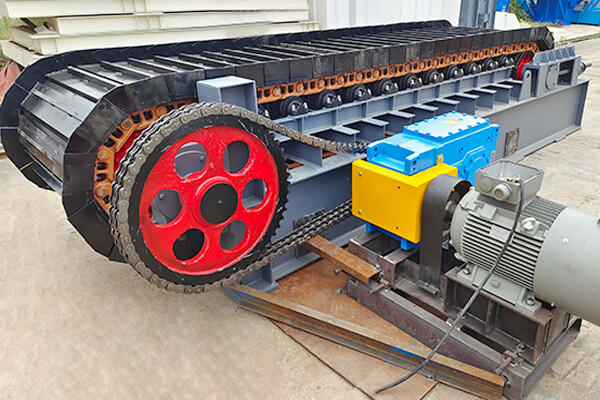

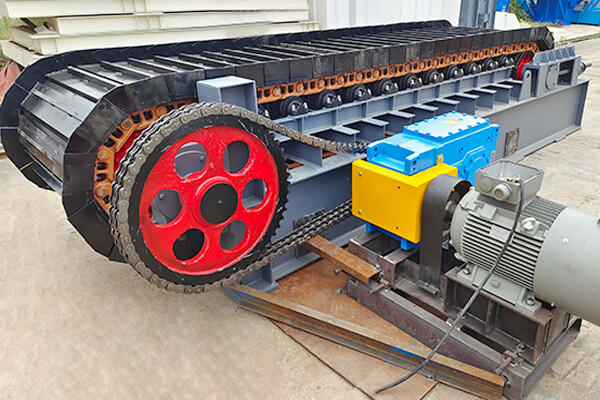

Columbia is our regular customer and has purchased

Apron feeders from our company for limestone treatment last year. Last year's Apron feeder was very demanding. But the quality of our products has won the trust of customers. So this August. The customer placed another order with us for Heavy Duty Apron Feeder. In order to ensure the quality of the customer's products, the customer chose our top apron feeder, and selected foreign cooperative brands Siemens Click and Flanders reducer as the driving unit. At the same time in the production process we pay close attention to the production schedule and product quality. We have completed the production of Apron feeders for our Colombian customers and completed the pilot operation and product quality testing last week. Our project manager has got in touch with our shipping partner and will arrange the delivery today.

July and August are the hottest two months in our northern region. However, in order to guarantee the production time and quality for our customers, Our company Excellent Machinery Co.,Ltd., have worked hard to fulfill our customers' orders on time despite all the difficulties, showing that we have big manufacturer’s responsible work attitude and wholehearted customer service purpose. We will continue to carry forward the attitude of not afraid of difficulties, work hard, maintain quality is the lifeline, development is the hard truth of the service concept to continue to produce more good products for customers.

.jpg)