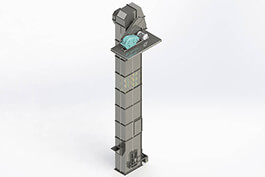

As a leading glass manufacturer in India, to commence production. Trivedi, an Indian client, is a glass manufacturing company. During its expansion, it required two sets of conveying equipment. After communicating with our engineers, the client determined that the needed equipment should have upper and lower horizontal sections. Our engineers ultimately selected our Z bucket elevator for the client. The raw material to be conveyed is cullets, with a processing capacity of 15 t/h, bulk density of 1.03.9 t/m³, bucket volume of 5L, bucket spacing of 189mm, bucket speed of 9~11 m/min, bucket material of SUS304, bucket quantity of 10 per meter, power of 9.2kW, ratio of 60.46, and a lifting height of 15m.

After multiple video conferences and on-site visits and inspections by the client, Trivedi finally decided to purchase two Z bucket elevators from our company. After receiving the client's order, our company held technical discussions, refined the drawings to ensure their accuracy, and then issued production notices to the production workshop. After more than two months of production, we completed the production in October 2024. We also shot relevant operation videos for the client, produced usage manuals, and conducted live inspections for the client. We carried out 48-hour no-load and load tests in our factory, including shaft temperature detection, current and voltage detection, noise detection, vibration detection, and paint film thickness detection. All tests were qualified and met the client's requirements. We completed the shipment on October 19, 2024. After our Z bucket elevator arrived at the client's site, we remotely guided the client through installation and initial commissioning. It is now operating normally and meeting the client's processing capacity expectations. On April 19, 2025, the client sent us the good news of the grand opening ceremony of the new factory. In the letter, the client highly praised the quality of our products and gave us extremely high evaluations for our services. They expressed gratitude for our timely provision of high-quality products. We will continue to provide ongoing support, helping the client solve production problems and offering maintenance and upgrade services.

.jpg)

We are a professional supplier of bulk material handling equipment, with over 30 years of experience in industries such as food, grain, cement, and chemicals. We have rich production and maintenance experience. To ensure product quality, we have invested heavily in advanced processing equipment such as bending machines, shearing machines, presses, automatic welding robots, and laser cutting machines. We have established a team of experienced engineers to provide high-quality services to our clients. We welcome domestic and foreign clients to visit our company for business discussions and cooperation.

.jpg)