The Russian client, a prominent engineering trading firm headquartered in Moscow, Russia, specializes in EPC (Engineering, Procurement, and Construction) projects for open-pit mining operations and equipment supply. With ongoing procurement requirements, the client has been actively seeking global suppliers for critical mining equipment, including

apron feeders and mineral sizers, to support their large-scale mining projects.

In 2025, the client initially connected with our company through a Google search, expressing a strong interest in establishing a collaborative partnership and requesting a site visit to our facilities. Following multiple rounds of detailed communications and meticulous preparation of technical documentation, product catalogs, and logistical arrangements, the client confirmed their visit for May 22, 2025, aiming to assess our capabilities firsthand.

Upon arrival, the client delegation was warmly received and accompanied by our Sales Manager, Mr. He, who guided them through a comprehensive tour of our premises. The itinerary included visits to our Technology R&D Center, Machining Workshop, Manufacturing Facility, Quality Control Laboratory, and After-Sales Service Department. These tours provided an in-depth overview of our end-to-end operations, from innovative product design to precision manufacturing and rigorous quality assurance processes.

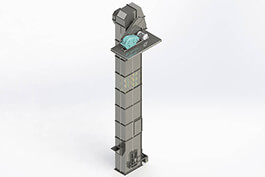

A key focus of the visit was the client’s evaluation of our flagship products: the apron feeders and mineral sizers. The Russian team closely inspected the equipment’s structural design, manufacturing craftsmanship, and operational demonstrations, raising detailed technical inquiries about performance parameters, maintenance requirements, and adaptability to harsh mining environments in Russia. Mr. He, with his extensive expertise in international trade and mining equipment, addressed each question with comprehensive, professional responses, supported by real-world case studies and data-driven insights. He also engaged in a thorough discussion with the client about operational best practices, including equipment installation guidelines, daily maintenance protocols, and safety considerations for using

apron feeders and mineral sizers in open-pit mining scenarios.

The Russian clients were highly impressed with the depth of our technical knowledge and the professionalism of our team. They specifically commended our state-of-the-art production equipment, advanced processing techniques , and meticulous quality control procedures. During the feedback session, they emphasized their appreciation for our “craftsmanship spirit”—a commitment to precision and durability evident in every stage of production—and praised our seamless coordination between sales, technical, and after-sales teams.

This visit marked a significant milestone in our bilateral relationship, fostering a deeper mutual understanding and trust. The client expressed strong confidence in our ability to deliver high-reliability equipment and tailored solutions that align with their project requirements. Looking ahead, both parties anticipate expanding collaboration in supply chain integration, technical support, and potential joint ventures in the Russian mining sector.

As a testament to our dedication, we remain committed to providing the Russian client with superior products and comprehensive services, leveraging our engineering expertise and customer-centric approach to drive long-term success in their EPC projects. The visit not only solidified our position as a trusted equipment supplier but also laid a robust foundation for sustainable, mutually beneficial growth in the global mining industry.